Sources of contamination in cleanrooms can be caused by a variety of factors, including:

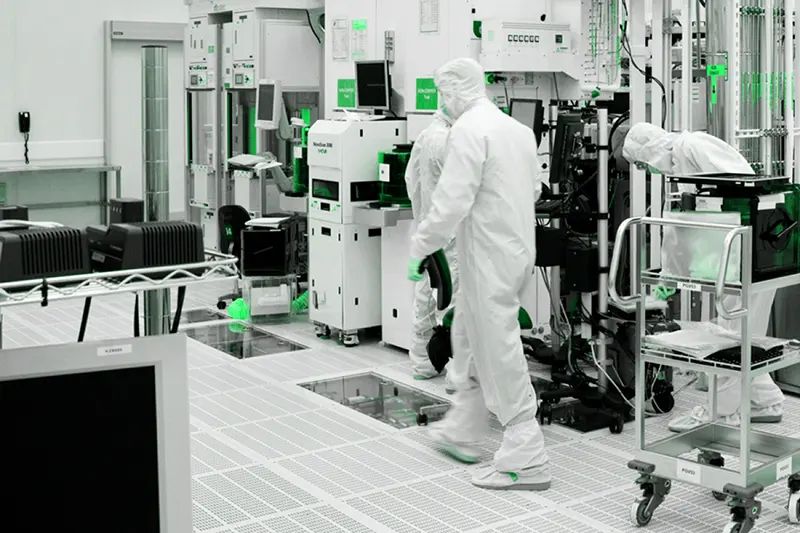

- People: People can be sources of contamination for cleanrooms, as they carry dust, microbes, and mold.

- Machinery: Machinery can also be sources of contamination for cleanrooms, as they can produce dust, particles, and oil.

- Materials: Materials that enter the cleanroom can also be sources of contamination, as they may carry dust, microbes, or mold.

- Air: Air can also be a source of contamination for cleanrooms, as it may contain dust, microbes, and mold.

Humans are the main source of contamination in cleanrooms

Yes, humans are the main source of contamination in cleanrooms. Humans constantly shed skin, hair, and dead cells, and this can accumulate in the cleanroom and lead to product spoilage. Humans can also transfer bacteria and viruses into the cleanroom, which can be harmful to products and workers.

To reduce human-caused contamination in cleanrooms, a variety of measures can be taken. These measures include:

- Wearing protective clothing, such as long gowns, caps, and masks.

- Washing hands before and after entering the cleanroom.

- Limiting the number of people in the cleanroom.

- Using hoods and air filters.

- Regularly cleaning and disinfecting the cleanroom.

By taking these measures, the risk of human-caused contamination in cleanrooms can be reduced and ensured that products and workers are not put at risk.

read more | Cleanroom Validation

Benefits of Reducing Human Contamination

Here are some of the benefits of reducing human contamination in cleanrooms:

- Improved product quality

- Reduced risk of product failure

- Reduced risk of bacterial and viral contamination

- Increased worker safety

- Reduced production costs

Reducing human contamination in cleanrooms is an important measure that can have many benefits for businesses.

To identify sources of contamination in cleanrooms, a variety of methods can be used, including:

- Visual inspections: Visual inspections can be used to identify sources of contamination such as dust, particles, and oil.

- Air testing: Air testing can be used to identify particles, microbes, and mold in the air.

- Particle tracking: Particle tracking can be used to identify the movement of particles in the cleanroom.

read more | Hygienic air conditioner

Ways to Control Contamination in Cleanrooms

Once the sources of contamination in a cleanroom have been identified, steps should be taken to control or eliminate them. Contamination control measures can include:

The Use of Proper Ventilation to Reduce Contamination in Cleanrooms

The ventilation system of a cleanroom must be designed to meet the specific needs of that room. Factors to consider include:

- The required cleanliness level

- The size of the room

- The type of activities performed in the room

- The equipment present in the room

The ventilation system must be able to filter the air to the required level. Filters used in cleanrooms are typically HEPA or ULPA filters, which can remove very small particles.

The ventilation system must be able to circulate air in the room effectively. This helps to remove particles and other contaminants from the air. The ventilation system must also be able to control the temperature and humidity of the air in the room. This helps to create a comfortable and safe environment for workers and equipment.

By using a proper ventilation system, contamination in the cleanroom can be minimized and a clean and sterile environment can be created for the production of sensitive products.

Here are some tips for using proper ventilation to reduce contamination in the cleanroom:

- Use HEPA filter or ULPA filters.

- Ensure that the ventilation system is able to circulate air in the room effectively.

- Control the temperature and humidity of the air in the room.

- Prevent contaminants from entering the room.

- Train workers on the importance of proper ventilation.

By following these tips, you can help to prevent contamination in the cleanroom and create a clean and sterile environment for the production of sensitive products.

The use of protective clothing to reduce contamination in cleanrooms

Protective clothing is essential for reducing contamination in cleanrooms. Cleanrooms are controlled environments designed for the production of sensitive products. Protective clothing helps to prevent the entry of particles and microorganisms into the cleanroom. This helps to ensure the quality of the products produced in the cleanroom.

There are various types of protective clothing that can be used for cleanrooms. The type of protective clothing required depends on the cleanroom class and the type of activity being performed in the cleanroom. Some common types of protective clothing used in cleanrooms include:

- Gown

- Pants

- Shoes

- Cap

- Mask

- Safety glasses

- Gloves

Protective clothing must be worn and maintained properly to be effective. Workers must put on their protective clothing before entering the cleanroom. Protective clothing should be clean and free of particles. Workers must put away their protective clothing in the appropriate place after leaving the cleanroom.

The use of protective clothing is essential for reducing contamination in the cleanroom. This helps to ensure the quality of the products produced in the cleanroom.

Here are some additional tips for using protective clothing in cleanrooms:

- Put on protective clothing before entering the cleanroom.

- Keep protective clothing clean and free of particles.

- Put away protective clothing in the appropriate place after leaving the cleanroom.

- Replace protective clothing immediately if it is damaged or dirty.

- Avoid touching your face while you are in the cleanroom.

- If you are sick, avoid entering the cleanroom.

By following these tips, you can help to maintain the cleanliness of the cleanroom and ensure the quality of the products produced in the cleanroom.

read more |Cleanroom Clothing

Using the Right Cleaning Products to Reduce Contamination

Here are some tips on using the right cleaning products to reduce contamination in a cleanroom:

- Use cleaning products that are designed for use in cleanrooms. These cleaning products are typically non-toxic, non-flammable, and odorless.

- Dilute cleaning products according to the manufacturer’s instructions. Over-diluting cleaning products can make them less effective.

- Use cleaning products that are appropriate for the type of surface you are cleaning. Some cleaning products are not suitable for use on certain surfaces, such as metal or plastic.

- Wear gloves and protective clothing when using cleaning products. This will help protect you from harmful substances in the cleaning products.

- Rinse surfaces with clean water after cleaning. This will help remove any residual cleaning products.

Here are some additional tips on cleaning cleanrooms:

- Clean regularly. This will help prevent the buildup of contamination.

- Use a regular cleaning schedule. This will help ensure that all surfaces are cleaned.

- Use trained personnel to clean cleanrooms. This will help ensure that the room is cleaned properly.

- Use appropriate cleaning equipment. This will help reduce the spread of contamination.

- After cleaning, ventilate the room thoroughly. This will help remove any cleaning product odors.

By following these tips, you can help reduce contamination in cleanrooms and maintain a clean and safe environment.

read more | Standard air conditioner

Training Employees to Reduce Contamination in a Cleanroom

Cleanrooms are controlled environments designed for the production of contamination-sensitive products and medical devices. To maintain contamination levels in cleanrooms, employees must be trained on how to minimize contamination.

Here are some tips on how to train employees to reduce contamination in cleanrooms:

- Train employees on the importance of contamination control in cleanrooms.

- Train employees on the types of contamination that can exist in cleanrooms.

- Train employees on the sources of contamination that can come from employees, equipment, and the environment.

- Train employees on methods for reducing contamination through cleaning, the use of covers, and adherence to dress protocols.

- Train employees on how to identify and report contamination.

By training employees on how to reduce contamination in cleanrooms, you can help ensure the production of high-quality products and medical devices.

Here are some additional tips for employee training:

- Tailor the training to the specific needs of your cleanroom.

- Use images and videos to help employees understand concepts.

- Use exercises and hands-on training to help employees learn how to apply their skills.

- Repeat the training regularly to keep employees up-to-date on the latest information.

By following these tips, you can ensure that your employees are trained to reduce contamination in cleanrooms and can help produce high-quality products and medical devices.

read more | What is a Class D cleanroom

By identifying and controlling sources of contamination, it is possible to prevent cleanroom contamination and ensure that products and processes produced in a cleanroom are free of contamination.

What is aseptic technique in a cleanroom?

Aseptic technique in a cleanroom is a set of methods and procedures used to prevent contamination in clean environments. These techniques are designed to prevent the spread of microorganisms, dust, and other contaminants.

Aseptic technique in a cleanroom includes the following steps:

- Wearing clean clothes. Employees working in a cleanroom must wear clean clothes, including a gown, hat, mask, and gloves. These clothes should be put on before entering the cleanroom and taken off after leaving the clean room.

- Washing hands. Employees must wash their hands with soap and water before entering the cleanroom and after contact with any contaminated surface.

- Using sterile tools. Tools used in a cleanroom must be sterile. These tools should be placed in a sterilizer and sterilized according to the manufacturer’s instructions.

- Working in a clean environment. The cleanroom must be regularly cleaned and disinfected. This is done to remove any microorganisms or contaminants that may be present in the air or on surfaces.

- Following specific instructions. There may be other specific instructions for aseptic technique in a cleanroom, which vary depending on the type of work being done. It is important to follow these specific instructions carefully to prevent contamination.

read more | Cleanroom softwall

Aseptic technique in a cleanroom is essential for protecting sensitive products and processes from contamination. By following these techniques, the risk of contamination can be reduced and ensured that products and processes are in the best possible condition.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: