Special rooms have their own special requirements. In a cleanroom, clean air must be provided with the appropriate exchange rate, adequate pressure, precise control of temperature, humidity, and air quality. To achieve all of these, a fan filter unit can be used. A fan filter unit is an air purifier that is essential for providing clean air in the cleanrooms of pharmaceutical, semiconductor, liquid crystal diode, and other manufacturing plants. This equipment is a flexible and economical solution for having clean air. Fan filters are usually installed on the grid ceiling in cleanrooms. In large cleanrooms, the number of fan filter units required may even reach several hundred. In this article, we will discuss fan filter units.

What is a fan filter unit?

A fan filter unit is a dual-purpose technology that simultaneously cleans room air with advanced filtration and increases airflow in the space in which it is installed using a motor-driven fan. These units offer many benefits for workplace health and safety and provide significant value compared to other technologies that offer similar functionality.

Fan filter units are typically used in facilities that require clean air and room air circulation, such as cleanrooms, specialized manufacturing, food, medicine, and scientific laboratories. The materials used to make this equipment can be divided into aluminum-zinc sheet, stainless steel sheet, aluminum alloy sheet, and powder-coated sheet.

read more | Mist shower

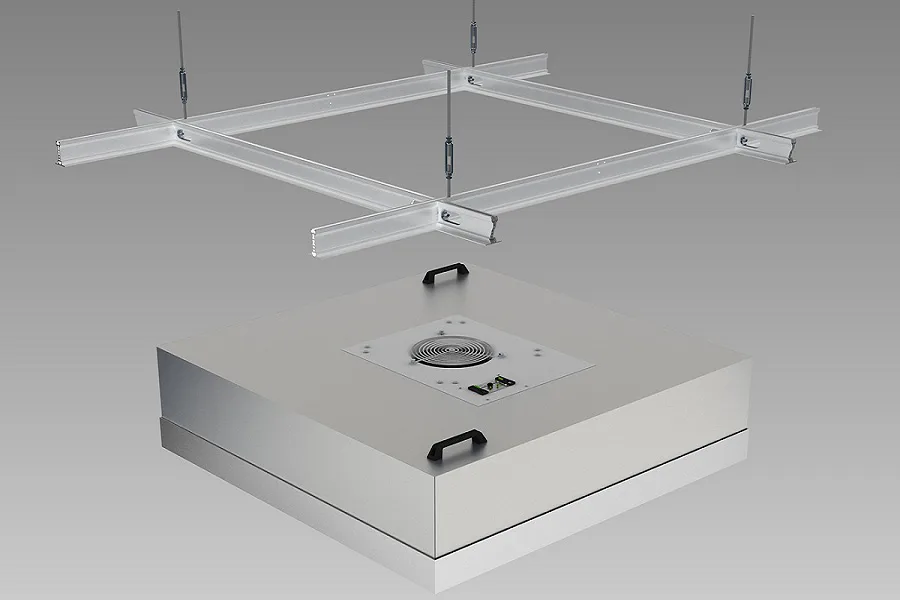

A fan filter unit is a motor-driven filtration system that is used to provide a continuous supply of clean, filtered air to a cleanroom. These units are installed within the room’s ceiling grid and operate independently or in conjunction with a HVAC system. The airflow in a cleanroom is designed to direct the air to floor or wall vents. The air is then either exhausted from the room or returned to the fan filter units in the ceiling.

Depending on the size of your cleanroom, you can add or subtract fan filter units to meet the required ISO class conditions. Typically, the more stringent the cleanroom cleanliness requirements, the more fan filter units will be required.

Structure of fan filter units

Fan filter units clean and circulate air to improve the working conditions of environments such as cleanrooms. First, one or more fan filter units are installed in the ceiling and integrated with the existing mechanical and electrical systems.

Filtration Unit Fan Components

Lightweight models can be a good option for this stage. After installation, a motor-driven fan is started, which circulates air through the filtration system. This way, by removing 99.99% of all pollutants, the air is purified. The structural components of the filtration unit fan are as follows:

- Housing: The filtration unit fan housing is made of galvanized steel, powder-coated steel, or SUS 304 stainless steel. It is worth mentioning that the housing material can also be selected according to customer needs. The housing thickness is about 1.2 to 2.0 centimeters.

- Pre-filter: The main function of the pre-filter is to prevent damage to the HEPA filter caused by debris.

- Fan: The fan sucks in air and blows it towards the HEPA filter.

- Filter: The filter used for the filtration unit fan is a HEPA or ULPA filter. In fact, it can be said that the most important part of the filtration unit fan is its filter, which filters the air and creates a fresh and clean environment.

- Controller Switch: The filtration unit fan is equipped with a three-level switch for speed control and an on/off switch, and there are three levels (low, medium, and high) for air speed control.

- Motor: AC and DC motors can be used. Of course, the DC motor is large and expensive, but it is easy to control. Some high-quality motors are lubricated without oil. These motors have sealed bearings, are equipped with thermal overload protection, and have a long service life.

- Air Duct Connection Parts: In cleanrooms with a low cleanliness level, there is no static pressure on the ceiling. Thus, the air duct connection parts make the connection between the air duct and the filtration unit fan easier.

How a fan filter unit works

To create cleanroom conditions, the smallest airborne contaminants (even smaller than one micron) must be removed from the air and circulated with positive pressure. Airborne contaminants can include dust, mold, smoke, fumes, viruses, bacteria, and more. To filter the air, a fan filter unit first screens out larger particles with a primary filter to prevent them from clogging up more complex filters. In the secondary stage, Air Fit uses a high-efficiency particulate air (HEPA) filter to remove up to 99.99% of particles smaller than one micron.

read more | cleanroom equipment

It is worth noting that HEPA filters are the highest known standard for air filtration technology. These filters work by driving air into a network of extremely fine artificial fibers that are randomly aligned. This causes any particle that tries to pass through the network to become trapped. When the air exits the filter, it is completely clean and ready to be transferred to a cleanroom or facility. As the air is cleaned and released, a motor-driven fan blows the air to create a higher flow rate.

The operation steps of the filter fan unit are as follows:

- The air is drawn in by the fan from outside

- Then it passes through the HEPA filter under pressure

- The HEPA filter traps dust, bacteria, and airborne particles, and the filtered air is released

Operation of Fan Filter Unit

Air is drawn into the unit through a fan, first through a pre-filter and then usually through a HEPA (high-efficiency particulate air) or ULPA (ultra-low particulate air) filter. These two types of filters remove suspended particles from the air. Thus, along with the frequency of air changes, the cleanliness of the room air will be guaranteed according to the technical specifications. For the fan filter unit, there are four types of control methods. Of course, the control methods must be selected according to the actual conditions. These methods are as follows:

- Continuous speed adjustment control mode

- Multi-speed switch control mode

- Computer control mode

- Remote control mode

What are the advantages of a cleanroom with a fan filter unit?

Fan filter units are designed to meet the requirements of cleanroom construction, operation, and maintenance. One reason for using this equipment is to reduce operational costs through energy savings. Another reason is to reduce construction costs due to the thin, lightweight, and compact structure of the fan filter unit. Fan filter units are also effective in reducing the initial cost of overall cleanroom design, such as noise considerations.

read more | Cleanroom Cleaning Equipment

Among the other advantages of fan filter units for cleanrooms, the following can be mentioned:

- Short construction time

- Ability to adjust the cleanliness level from class 1 to class 1000 in different areas

- Low leakage potential due to the fact that the side opposite the ceiling has a low pressure

- The arrangement of fan filter units determines the cleanroom construction method to some extent

- Ability to adjust air speed in each area

- Ability to increase or change the flexibility of the cleanroom due to the layout of fan filter units

Technical specifications of fan filter units

As mentioned, fan filter units are used to supply and fill cleanrooms with ultra-clean air in sensitive industries such as food and pharmaceuticals. Therefore, these equipment must have precise technical specifications to meet the standard requirements. The important specifications of fan filter units are as follows:

- Size: Fan filter units are typically available in two common sizes: 1175x575x250 mm and 575x575x250 mm.

- Airflow: The airflow of the fan filter unit is close to 1000 to 1200 cubic meters per hour for FFU1175 and 600 cubic meters per hour for FFU575.

- Noise level: The noise in non-unidirectional airflow should not be louder than 60 decibels. At the same time, the noise in unidirectional airflow should not be more than 65 decibels. Therefore, when selecting a fan filter unit, the noise level of the fan filter unit is as low as possible.

- Air speed: The average air speed is about 0.45 meters per second.

- Control system: DC motor saves energy. This motor has intelligent control and less noise. In contrast, AC motor has louder noise. It is worth mentioning that AC motor is much cheaper than DC motor.

- Air filter: HEPA or ULPA filter is usually used in fan filter units. HEPA filter with efficiency up to 99.99% in particles of 0.3 microns, ULPA filter with efficiency up to 99.99% in particles of 0.1 microns.

- Blowing wheel: There are two types of blowing wheels, namely the centrifugal type with forward curvature and the centrifugal type with backward curvature. The forward type provides a large volume of air and increases the possibility of dust removal, while the backward type reduces energy consumption and noise.

How to Choose a Filter Unit Fan

Choosing a filter unit fan requires careful consideration. Air purification and removal of the smallest particles form the basis of ISO 14644 standards and make the filtration system a logical starting point. There are usually two types of filter unit fans: standard and non-standard or custom.

read more | Package unit

If there are no special conditions, you can choose a standard filter unit fan; of course, as long as this equipment can meet the requirements of standard parameters. On the other hand, if the standard filter unit fan cannot meet the requirements, you can customize it. The filter unit fan can be customized according to the different needs of different customers. For this, the materials and size of this equipment will usually change. But if there are specific needs, other parameters can be changed. It is worth mentioning that standard filter unit fans are more readily available and the production of the non-standard or custom type takes time.

What is the difference between DC and AC filter unit fans?

Two types of motors are used for filter fans, namely DC and AC. It can be said that the DC filter unit fan has more advantages than the AC type. In fact, DC is the improved version of AC. The purpose of designing and manufacturing the DC filter unit fan was to help protect the environment and save energy. This type of equipment is widely used because it provides the possibility of group control of the unit control fan.

However, it should be considered that the price of the DC unit control fan is higher than the AC type. In general, it should be said that the choice of either of these two types depends on your needs. It is worth mentioning that the life of the filter unit fan motor is between 40,000 and 100,000 hours.

Variable Speed Fan Filter Unit Systems for Cleanrooms

Variable speed fan filter unit drive systems are a state-of-the-art product that maintains fan output speed settings under filter load (or when changing production conditions require increased operators and particulate load).

Features of variable speed fan filter unit systems for cleanrooms include:

- Fan filter units can be controlled individually or in groups; typically one to four units per address.

- Fan speed is set from a console located outside the cleanroom. This is done without compromising the integrity of the cleanroom. It is worth noting that settings are possible by individual address, zone, or globally.

- The number of addresses is virtually unlimited.

- Room or equipment layout with unique airflow requirements is easily adjustable and controllable.

Important Standard for Cleanroom Fan Filter Unit

In the manufacturing process of cleanroom fan filter unit as one of the most practical and important devices in cleanrooms, it is very important to follow several points, one of which is the uniformity of the exhaust airflow. The clean air produced by the cleanroom fan filter unit must be introduced into the cleanroom space with a uniform airflow from the outlet of the unit.

read more | Standard air conditioner

To ensure the standard airflow, the difference in the exhaust air speed of several different points of the cleanroom fan filter unit will be measured, and this difference in speed should not be higher than 15%. According to the standard, the average exhaust air of the cleanroom fan filter unit should be between 0104-FPM 90. If the exhaust airflow speed of the cleanroom fan filter unit is more than this amount, we will see a decrease in the cleanliness of the room air.

Buy Fan Filter Unit from Ekeas

A cleanroom without a fan filter unit is not a standard cleanroom. The technology used in this equipment ensures the required air circulation. The fan filter unit also prevents air pollution during the production of sensitive products.

Ekeas is a leading manufacturer of cleanrooms and related equipment. At Akia, we offer a variety of air purification solutions to meet the needs and expectations of your cleanroom. For more information about fan filter units and purchasing them, please contact our experts at Ekeas.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: