Clean air circulation in sensitive environments such as healthcare centers and the purification of harmful exhaust air in factories that emit pollutants into the environment is of great importance. For this reason, the use of fan filter boxes equipped with filters is recommended to clean the air from various pollutants. This device is placed in the path of incoming or outgoing air and prevents the release of suspended particles. Fan filter boxes provide the highest air quality to employees and in this way help to maintain their health and increase the useful life of the electrofan. In this article, we intend to learn about the operating method, specifications and applications of fan filter boxes.

What is a fan filter box?

In many places, providing clean air free of any pollutants is a necessary need. This need should be taken into account when designing air intake systems. One of these components is the use of fan filter boxes in places that require a high degree of air purity; cleanrooms. In a cleanroom, a controlled volume of suspended particles should be present in each cubic meter of air. Fan filter boxes are also used in industrial factories equipped with cleanrooms to prevent the release of contaminated exhaust air into the air. This device, by filtering the air, provides standard conditions for working in a cleanroom.

The function of a fan filter box is to clean the air of any particles that may be present. This is done through multi-stage filtration. A specific method is designed for each stage of filtration in this device. Inertia, trapping, or diffusion are usually used. With the help of these methods, particles in the air stick to the filter and then clean air passes through it.

The advantages of using a fan filter box

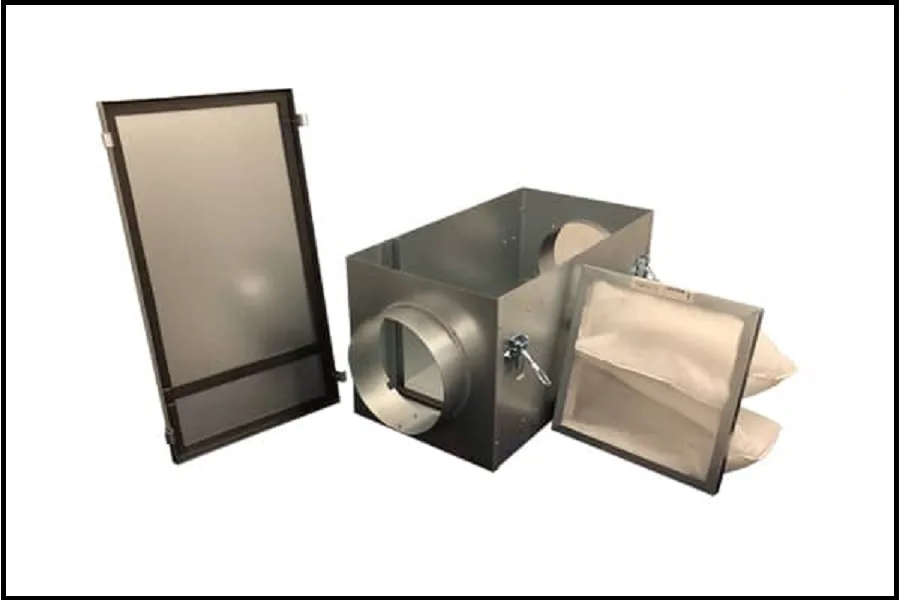

A fan filter box returns air to the cleanroom. This device has the ability to filter the return air. The act of returning air to the cleanroom is called exhaust. Additionally, a fan filter box can increase the input and output of the system; so that if the environment needs more input, you can use a fan filter box with multiple openings. Of course, fan filter box systems are produced in two models, namely metal filter box and panel or silent. Using any of the types of fan filter boxes has many advantages, some of which are as follows:

- Reduction of noise in the cleanroom

- Prevention of the entry of pollutants into the cleanroom

- Proper distribution of air in different parts of the cleanroom

- Applications of fan filter box

All industries are trying to preserve the health of their staff with new technologies in any way they can. Clean air is also one of the requirements that is very important for people’s health. For this reason, fan filter boxes are used in centers where pollution is very high and sensitive to pollution (such as cleanrooms). These boxes take the polluted air and then filter them with HEPA or ULPA filters. Thus, the entry of particles into the air is prevented.

Filter box is installed in a location where polluted air enters from one environment to another. Therefore, these filters are used to prevent the passage of polluted air. The filter box fan consists of three parts: an outlet, an inlet, and a return air valve that ensures proper filter operation. For better performance of the filter box fan, you must also ensure air tightness of the valve and its engagement.

read more | Standard air conditioner

These filters, which are often installed in the ceiling, are made of galvanized material. Of course, for better aesthetics and higher quality durability, the filter box fan is coated with electrostatic paint. It is worth mentioning that filter boxes are not only used for air purification, but can also be used to reduce noise. It is important to note that these boxes require a fan and filter for better performance.

Among the other applications of the filter box fan, it can be mentioned to reduce the amount of noise. In fact, it can be said that using it and installing filters suitable for the type of use in the path of incoming air, to a large extent prevents environmental pollution and increases the useful life of the fan.

Use in cleanroom; the most important application of filter box fan

Choosing a suitable filter for the filter box is the most important point in the application of the filter box. This filter must be compatible with the class of the cleanroom. Failure to comply with this issue in cleanrooms that require special filtration can have irreparable consequences.

Many workplaces or healthcare centers unintentionally emit polluted air. This causes suspended particles to enter the air. This is where the filter box fan comes into play to prevent this pollution.

Fan filter box can be used in any environment that produces polluted air but needs clean air. Healthcare centers such as laboratories and hospitals are among these. However, pharmaceutical or chemical industries such as petrochemical factories and even other industries such as biotechnology may need such equipment more than other places. Among the applications of fan filter box in cleanrooms, the following industries can be mentioned:

- Pharmaceutical industries

- Chemical industries

- Biotechnology industries

- Food industries

- Microelectronic industries

- Medical equipment industries

- Laboratories and research centers

- Healthcare centers and hospitals

Fan filter box working method

The location of the fan filter box is in the air intake section. The air is sucked in by the centrifugal fan and enters the device. The fan filter box is equipped with several stages of filtration. These stages, by trapping particles in one of the three methods of inertia force, sticking, scattering, and dispersion, absorb the dust and suspended particles present in the air and bring about the cleanliness of the airflow.

read more | Hygienic air conditioner

The filters used in this device have high absorption power. Usually, HEPA and ULPA filters are used to absorb particles up to 99.99%. If necessary, a silencer or fan silencer can be used in the fan filter box to prevent noise from the fan. This technology prevents the noise of the fan from spreading into the duct or duct. Fan filter boxes are designed in different sizes according to the required capacity. Air handling units and air washers are also considered to be a type of filter box.

Components of the fan filter box

The fan filter box is made up of multiple sections for better performance. If any of these components cannot function well, the result will be substandard air. The inlet and outlet valves, as well as the return air in the cleanroom, must be completely sealed. In this way, the air is completely filtered and this filtered air is distributed evenly in the cleanroom space.

read more | What is a Pre-filter?

After the various parts are screwed together, they are covered with a layer of paint and special rubbers. The reason for doing this is to protect the parts from corrosion. This also makes it easy to disassemble these parts, while increasing the life of the device.

Filter chamber has several parts. These filters are placed in the plenum section and form the main part of a filter box fan. One part of the chamber is made of aluminum. A bag filter is placed in the other part, which can be easily replaced. In the third section, HEPA and EPA filters are also installed. It is worth mentioning that these devices produce a lot of noise and a silencer is used to control the noise level.

To access these filters after installation, a door is placed that must be well insulated and sealed to ensure the quality of the filter and its performance. Finally, an air inlet and outlet duct is placed, which is either located on the side or on the top of this device. In the following, the most important components of the filter box fan will be described.

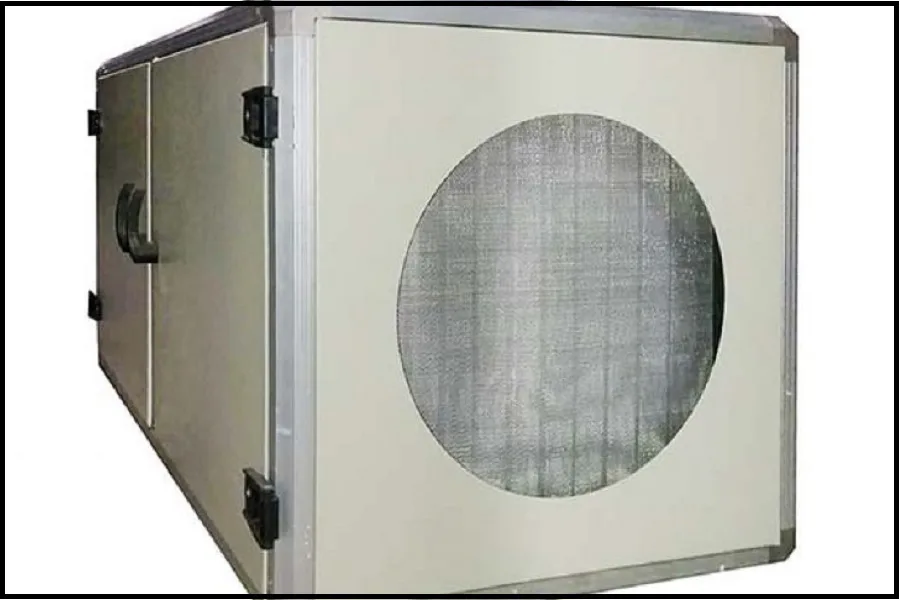

Filter box body

The filter body or plenum is the most important part of this tool and is made of galvanized or steel with a furnace paint coating. This coating is double-walled and the space between the two walls is filled with elastomeric insulation. This body has a completely bolted structure. This structure is designed to prevent corrosion, increase the life of the device, and also be able to be assembled and disassembled. After painting, the sheets are closed and airtight using special rubbers of the structure profile.

Electrofan; one of the key components of the filter box fan

Another component of the filter box fan is the electrofan. The electrofan is made of backward (backward), forward (forward) or comfy fan. This section has static and dynamic balance according to ISO 1940 standard. The electrofan is equipped with vibration dampers of the fan and motor for the suspension system.

read more | Cleanroom Control and Monitoring

Air inlet and outlet duct

Among the other parts in the filter box body, the air inlet and outlet duct is also located. This section, which is located on the side or top of the filter box body, is responsible for the entry or exit of air from the filter box to the main duct of the air conditioner.

Filter box chassis

There is also a chassis in the filter box fan. The design of the chassis is carried out according to the factory gutter. The design of the chassis is done according to the capacity and volume. This part is covered with paint after welding and milling operations.

Filter chamber

The filter chamber has several levels. The first bed is made of aluminum and is flat-type. The second bed is a replaceable bag filter. Next, the third bed is covered with HEPA and Ulpa filters with high absorption coefficient.

Filter; the most important part in the filter box fan

The most important part of the filter box fan is the filter that is installed in the plenum box. This filter is placed inside the filter box, depending on the application and class of the cleanroom, of the HEPA and EPA type. These filters have high absorption power. It can even be said that they absorb up to 99.99% of pollutants. To reduce the noise of the fan, a silencer is used inside the device.

Fresh and recirculating air dampers

Air dampers are of the OBD type with an aluminum blade and an Airfoil section that are made for better sealing and less pressure drop. Gears, dampers, and bushings are made of nylon to make them smooth to open and close.

read more | Mist shower

Solar diffuser

One of the decorative components of the filter box that ensures optimal air distribution in the environment is the solar diffuser. This part of the fan filter box is produced in different designs from aluminum with oven-baked paint coating. The function of the solar diffuser is to distribute air evenly in the environment. The solar diffuser is installed in the outlet of the fan filter box.

The main function of the solar diffuser is to prevent the uneven, vertical and disproportionate air throw. By rotating the airflow of the fan filter box through the solar diffuser, the filtered air is injected into all parts of the cleanroom with a reasonable and proportional acceleration and pressure. In fact, what you see after installing the fan filter box is this solar diffuser or ceiling diffuser. This part is made of aluminum in different designs and colors.

Installation location of the fan filter box

Generally, the fan filter box is installed on the ceiling. However, the type of filter used in it depends on the environment in which it is placed. This device is used at the end of the air outlet or inlet in the channels of ventilation systems. This device is placed in front of the air vents. It doesn’t matter what kind of vents they are. For example, fan filter box can be used for supply air vents or return air vents.

ekeas; Manufacturer of various cleanroom equipment in Iran

Providing healthy air is a requirement for many places, especially cleanrooms. This requirement can be easily met by using a fan filter box. This device also has the ability to reduce the noise produced by ventilation systems. ekeas, a knowledge-based company, is a cleanroom manufacturer in Iran. We offer the latest equipment at a very competitive price, depending on the sensitivity of the cleanroom you are looking for. For more information about fan filter boxes, please contact our experts.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: