Cleanrooms play a vital role in many industries, such as pharmaceuticals and medical device manufacturing. Many of the production processes in these industries are carried out in cleanrooms, and the introduction of even the smallest contaminant can significantly impact product quality. Without proper monitoring and control, dust particles can easily enter the cleanroom environment due to their small size and contaminate the environment. For this reason, air filtration in cleanrooms is of paramount importance. Bag filters are one of the most effective tools for preventing dust particles from entering cleanrooms. These devices are manufactured in a variety of sizes to meet the standards of each company.

What is a bag filter?

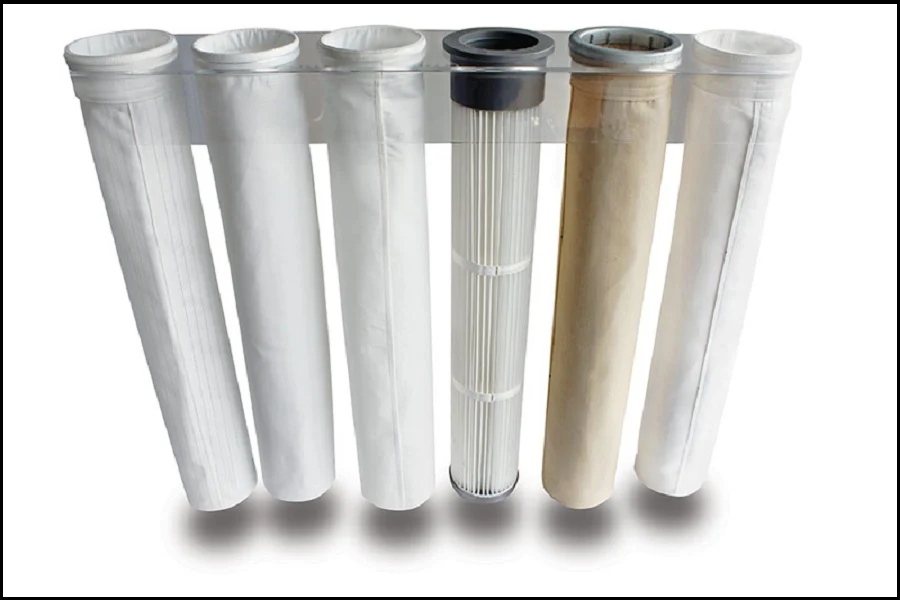

If you are looking to create an environment free of dust, you need to use bag filters in your cleanroom air filtration system. Bag filters, also known as baghouse filters, are typically made of polyester and are installed after or before the ventilation system fan. In this way, fine dust particles pass through the inlet port of the bag and settle on the outer surface. This ensures that clean air enters the cleanroom environment. The use of bag filters for air filtration in industries such as pharmaceuticals is essential.

Usually, there is a specific schedule for separating dust particles from the surface of bag filters. Bag filters are shaken using special methods according to the predetermined schedule, and the dust on the outer surface of them is transferred to the lower funnels. Then, dust and pollution are also discharged from inside the lower funnels with the help of a rotary valve. Usually, we need a lot of air pressure to do this.

read more | What is a HEPA filter

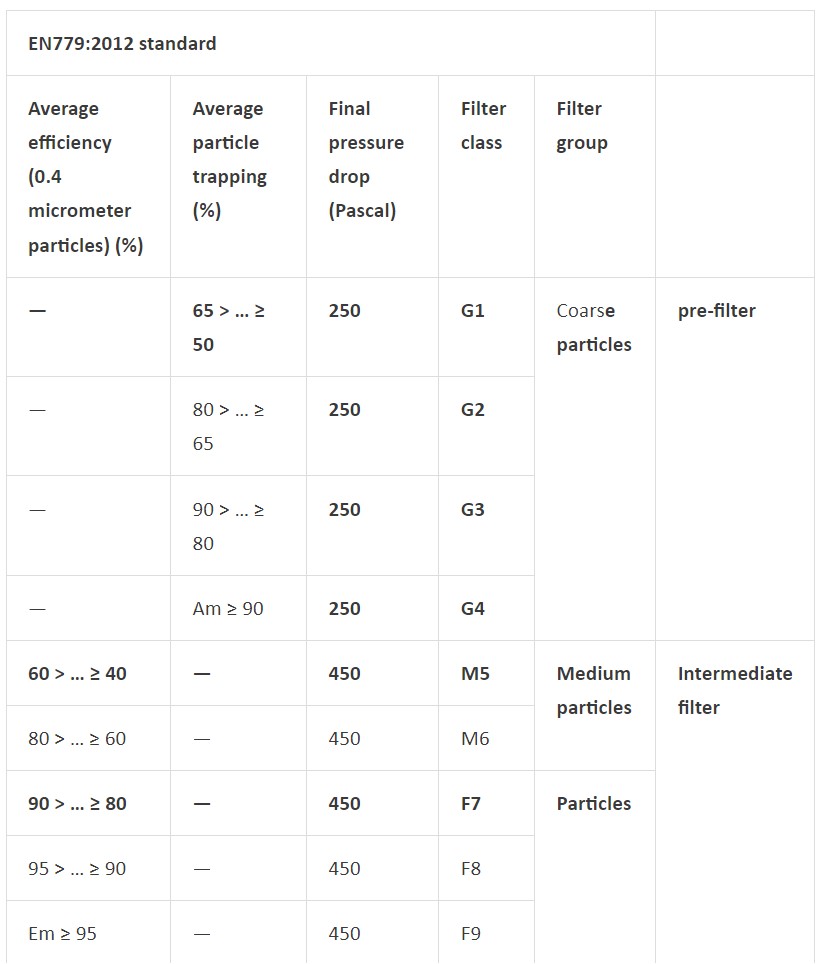

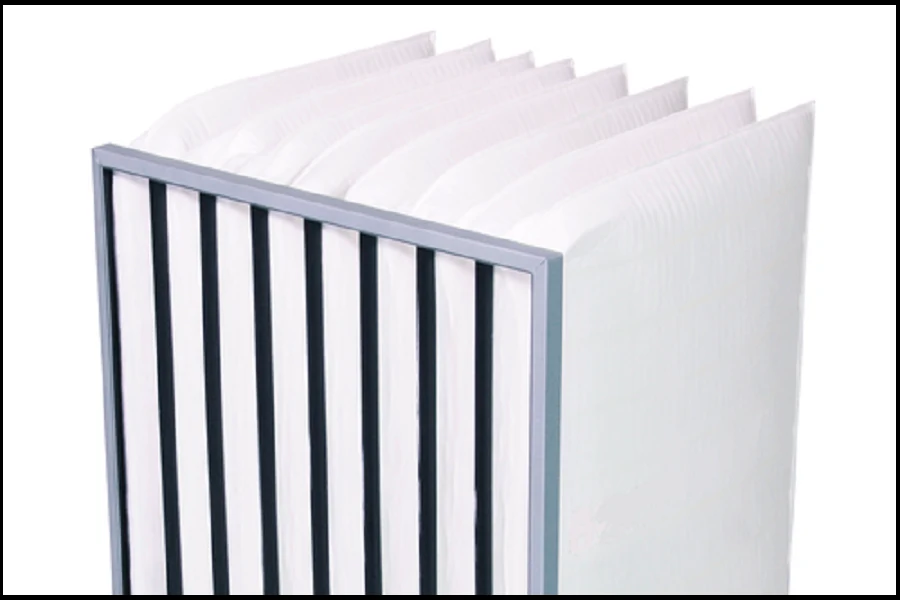

Bag filters are used to remove particles with medium and fine sizes in the filtration system. Intermediate filters are often installed after pre-filters and before high-efficiency filters. Intermediate filters are generally in the form of bags and the media material is glass fiber. Intermediate filters are available in standard and custom sizes.

The frame of the pre-filters can be made of aluminum, galvanized or ABS (plastic).

What are the uses of bag filters?

As we mentioned, the bag filter is a very high efficiency dedusting system that is used for air purification in many different places and industries, especially in cleanrooms. Usually, the vertical bags used in bag filters have a diameter of about 140 to 200 mm and a height of about 2300 to 3200 mm.

Bag filters can prevent the passage of micron-sized pollutants. This system is located inside a metal enclosure and the air is completely filtered by passing through it and then enters the desired environment. Proper design of bag filters for the desired environment can increase the efficiency of this equipment to over 95%.

read more | What is a Pre-filter

How does a bag filter clean the air of a cleanroom?

A bag filter is usually cylindrical in shape with cubical-shaped chambers, with a 60-degree sloped funnel located at the bottom of each for dust discharge. The interior of the cubical sections of bag filters is connected to a type of basket that holds the filter.

Air purification using a bag filter is a relatively simple process. Contaminated air containing dust is sucked in by a centrifugal device and transferred to the device’s pipes. Then, the air is purified by passing through the bag filter and leaves its dust on the surface of the fabric of this filter. The clean air is transferred to the top of the chamber and is finally returned to the cleanroom environment by a vacuum cleaner.

How to increase the efficiency of cleanroom bag filters?

As time goes by and dust and dirt are absorbed by the bag filter, the thickness of the fibers of this filter gradually increases. The accumulation of dirt and the increase in the thickness of the bag filter fibers cause a decrease in the efficiency of this vital and practical system. A decrease in the efficiency of this device means the entry of dust into the cleanroom environment and affecting the quality of products. For this reason, it is necessary to reduce the amount of dust on the fibers of bag filters using specific solutions in order to restore their efficiency to normal.

read more | Fan filter box

Two methods are usually used to increase the efficiency of cleanroom bag filters:

- Dusting with the pulse jet method

- Dusting by mechanical method

Dust removal of bag filters using the pulse jet method

To dust bag filters using the pulse jet method, air with a specific frequency and pressure that is determined according to the environmental conditions is injected into the bags. The injection of air into the bag filter causes the layers of dust on the fibers of this filter to break and disappear. In this way, the efficiency of the bag filter can be increased and the entry of dirt into the cleanroom can be prevented.

Increasing the efficiency of bag filters mechanically

The mechanical method is simpler than the jet pulse method. In the mechanical method of dust removal, a swinging motion is usually used along the longitudinal and transverse axes. However, the bag filter usually resists some of the dynamic loads applied in this method. This factor is recognized as one of the major disadvantages of the mechanical method.

read more | Cleanroom Door

Proper time for replacing bag filters

Although replacing the bag filter on time may increase the cost of maintaining a cleanroom, remember that delaying the filter replacement process can also cause serious damage. Delaying the filter replacement time can cause pipe blockage and clogging, increase the pressure on electric motors, increase system temperature, and put more pressure on fans. It is also possible that your staff will be exposed to various pollutants, which could endanger their health. As a result, be sure that by replacing the bag filter on time, you will prevent many additional costs.

Entrust the construction and equipping of your cleanroom to Ekeas

Many industries, especially in the medical and pharmaceutical fields, use cleanrooms to conduct experiments and produce their various products. A cleanroom is an isolated space where the environment must be free of any contamination. Ekeas Group is one of the leading companies active in the field of design, construction, implementation, and equipping of cleanrooms that operates in accordance with international standards. You can contact our experts for the design and implementation of a cleanroom or to purchase functional and essential equipment for your cleanroom, such as bag filters.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: