Cleanroom air shower

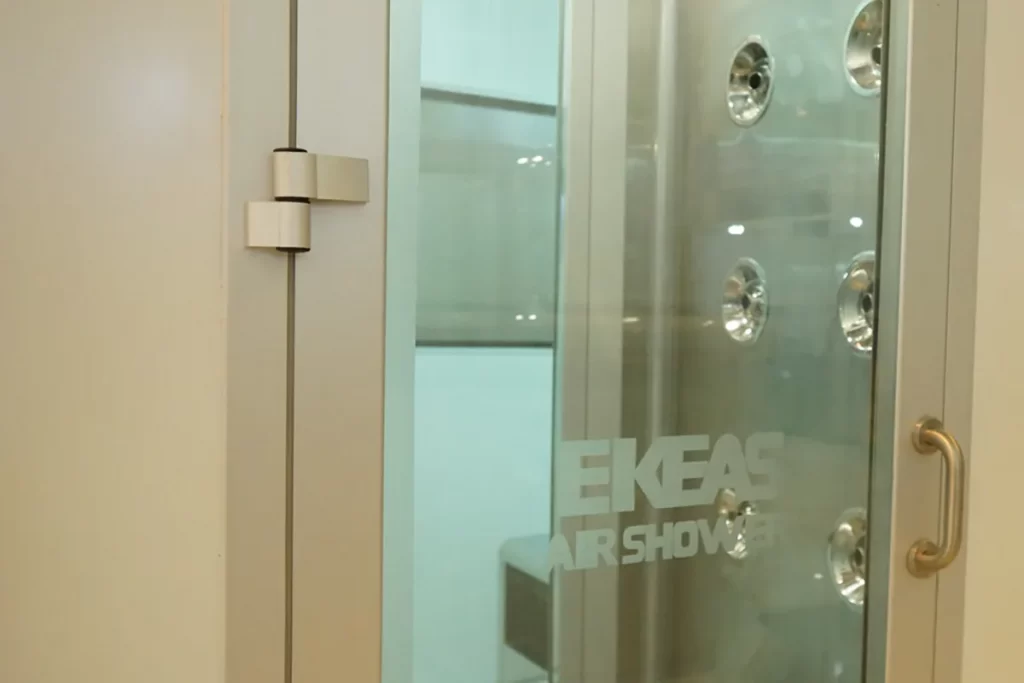

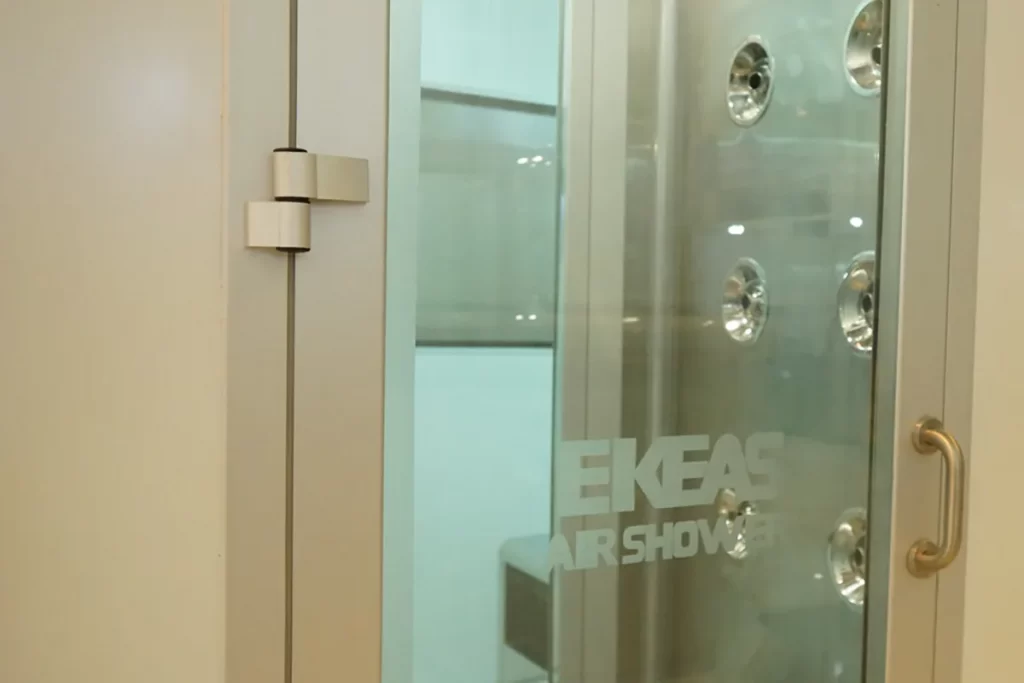

Air shower (air shower) is one of the equipment of cleanrooms that is installed at the entrance of cleanrooms and is responsible for minimizing the particle deposited on the clothes of staff. When the cleanroom staff intend to enter the cleanroom, they first open the door of the air shower and enter the air shower cabin. When the person is in the cabin, the person’s sight sensor detects the presence of the person and both doors are locked. Then the air shower starts working and the wind with a speed of more than 25 meters per second is blown onto the clothes of the staff through the nozzles provided on the sides and top of the cabin.

The operating time of the air shower is adjustable and can be changed from 1-999 seconds. Also, the nozzles provided in the air shower have the ability to adjust the angle of wind projection in 360 degrees, which increases the efficiency of the air shower. The air shower is equipped with two filter beds including G4 and H13/H14, which can also be changed according to the type of order and application.

The main components of an air shower can be listed as follows:

In general, air showers (air showers) are divided into 4 categories by material:

read more | Applications of cleanrooms in different industries

Air showers are used in a variety of industries.

In fact, it can be said that the small air shower room plays the role of a sterile room, and all people must pass through this room to enter and exit that area. Because the presence of any bacteria in the cleanroom can disrupt the workflow and even the efficiency of devices. The air shower, through the holes created in the walls and ceiling, blows air out with great intensity so that any contamination, poison, and even chemicals that exist on the employees’ special clothing are completely cleaned.

Please note that passing through this room is not only done when entering the cleanroom. But all people must also pass through this room when leaving. Because when working in a cleanroom, it is possible that various rays and poisons may be placed on their clothes.

read more| cleanroom equipment

Each of the tools and equipment of the cleanroom, according to the facilities they have, their characteristics and applications are highlighted. For the air shower, it can also be said that the existence of a series of equipment and facilities makes this system have a wide application in the cleanroom, which in this section we refer to some of the facilities of this smart and safe room.

Air shower is an indispensable equipment for cleanroom, regardless of any issue. Certainly, the priority and one of the most important requirements of work is to maintain the hygiene of the environment and preserve it in the cleanroom, which this possibility will be realized by the air shower. Over the past few years, gradually after conducting a series of research and explorations, people came to the conclusion that air shower is the most suitable, practical and economical method for maintaining the cleanliness of the environment in the cleanroom. In other words, the air pressure chamber that is installed and controlled in the entrance and exit of the cleanroom is called air shower.

read more | Cleanroom Validation

Before entering the cleanroom, people must be completely sterilized in this room called air shower (shower). Otherwise, they cannot enter the cleanroom. Some people think of air showers as bathroom showers. But I must say, contrary to what people think. A cleanroom air shower is a room with a series of chambers in different parts of it. From inside these chambers, disinfectants and clean air are released, and all the person’s clothes and equipment are cleaned and sterilized.

Conclusion

Experts always prefer to go to reputable centers that provide people with standard goods to purchase various equipment, such as air showers. But this type of purchase is time-consuming and costly, so we recommend that they purchase these products online from the Akyas website with the guidance and advice of experts.

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: