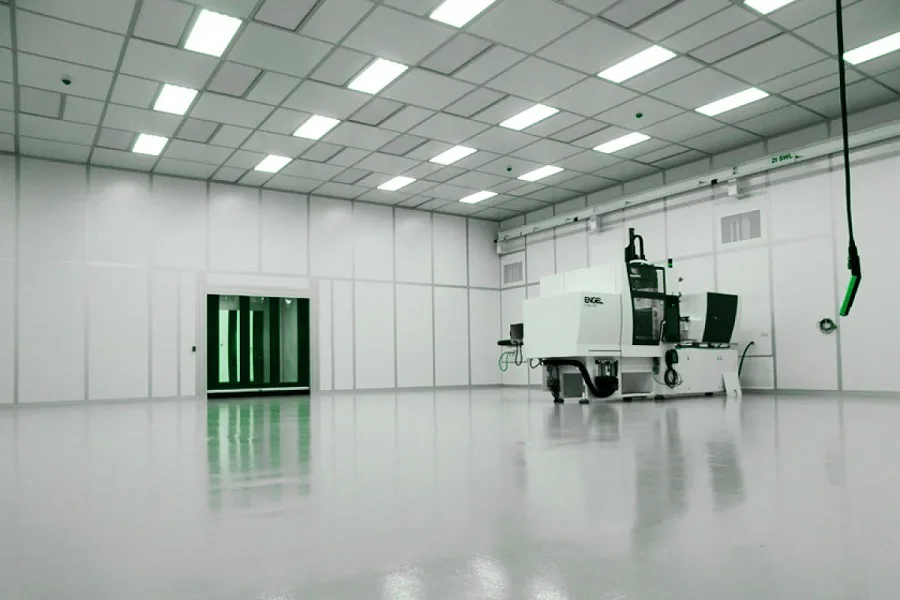

Cleanrooms are widely used in various industries such as medicine, pharmaceuticals, agriculture, environmental protection, and food processing. Cleanrooms are designed and implemented according to different standards and in different classes. Maintaining the cleanliness of the cleanroom and preventing the entry of any foreign contaminants is of great importance. The lack of isolation of the cleanroom environment can cause contamination of equipment and products produced in this space and severely affect their quality. For this reason, the use of cleanroom cleaning equipment is essential. A wide range of equipment is used to clean cleanrooms, such as various detergents and disinfectants, air purification systems, air showers, etc.

Chemical disinfectants

Chemicals play an undeniable role in cleaning cleanrooms. Your cleanroom may be equipped with various air filtration systems, but still, some contaminants may enter the environment. The majority of these contaminants enter the cleanroom through human force and you must use various disinfectants to remove them. Usually, in the cleanroom, various detergents and disinfectants are used to remove contaminants on various surfaces. In the following, we will introduce the types of these cleanroom cleaning equipment.

The criteria for choosing detergents

In choosing the right detergent for cleaning a cleanroom, two basic considerations are usually taken into account. The first important criterion for choosing a detergent is to pay attention to its chemical composition. Most detergents are chemically non-ionic and neutral solutions. It is recommended that you choose options with less foam for choosing the right detergent for disinfecting various surfaces inside the cleanroom.

read more | What is a weighing or sampling room

On the other hand, when choosing these cleanroom cleaning equipment, pay attention to the fact that your detergent must be compatible with the disinfectants used. If these two substances are not compatible with each other, detergents can reduce the biocidal properties of disinfectants and negatively affect their performance.

The most common detergents used for cleaning cleanrooms are:

- Types of soaps

- Anionic detergents

- Cationic detergents

- Non-ionic detergents

- Acidic detergents

- Alkaline detergents

- Amphoteric detergents

Criteria for selecting a suitable disinfectant for a cleanroom

A disinfectant is a chemical agent that can be applied to various surfaces in a cleanroom to kill harmful microorganisms. Disinfectants are available in a variety of forms and each has a different mode of action. Choosing the right disinfectant is of utmost importance in industries such as pharmaceuticals. Disinfectants are generally divided into two categories: oxidizing and non-oxidizing.

One of the most important criteria in the selection of disinfectants is that the material in question has a wide range of activity. In other words, the disinfectant should be able to have an acceptable effect on various vegetative microorganisms such as Gram-positive and Gram-negative bacteria.

In addition, these cleanroom cleaning equipment should have high speed or a reasonable contact time. The contact time refers to the amount of time that the disinfectant needs to have an effect on microorganisms. It is usually recommended to use disinfectants with a contact time of less than 10 minutes for cleanroom cleaning.

Other important criteria for selecting a disinfectant include:

- Employee health and safety

- Cost

- Type of microorganisms

- Compatibility with cleaning agents used

- Compatibility with various surfaces to be disinfected

Use of specific cleaning tools for cleanroom cleaning

Cleaning tools are one of the equipment for cleaning cleanrooms that should be carefully selected. Usually, for applying standard cleaning agents and disinfectants for cleaning various surfaces of cleanrooms, mop heads and various lint-free cloths are used. The most important factor in choosing a suitable cleaning tool is that the fabric used should be non-woven and should not produce any particles or lint. Because these lint can cause contamination of the cleanroom environment and affect the quality of products.

read more | Cleanroom Door

Cleaning supplies used for cleanroom are usually made of cellulose and polyester, and have a very high capacity for holding liquids in their fabric. Also, these fabrics and towels should have acceptable performance in removing non-viable particles and be able to apply the foaming and disinfectant agent well on the desired surfaces. By choosing the right cleaning supplies for cleanroom, you can remove much of the existing pollution in the room environment. Remember that all cleaning supplies must be completely disinfected before entering the cleanroom.

Air Shower is One of the Most Important Cleanroom Cleaning Equipment

It is not possible to set up a cleanroom without installing cleanroom cleaning equipment such as air showers. Because in the absence of these equipment, pollution can easily enter the cleanroom environment. Air shower is actually a high-performance cleaning path that is used to clean people and equipment entering the cleanroom. Air shower minimizes the amount of pollution entering the cleanroom environment. Employees, equipment, and various devices are cleaned under air showers using pressurized air when entering the cleanroom.

read more | Cleanroom Validation

Use of Filter in Air Handling Systems

Cleanroom air handling system equipment is designed and installed according to the class of the room. Air handling systems can be one of the factors in the entry of pollution into the cleanroom environment, so usually various types of air filters are used in the outlet section of these systems. The function of these filters is to prevent the entry of fine dust particles into the cleanroom environment. These cleanroom cleaning equipment can hold particles with dimensions close to 0.5 microns in their fibers. HEPA filters are one of the most practical types of air filters.

How often is it necessary to use cleanroom cleaning equipment?

Cleaning a cleanroom at the necessary intervals is just as important as using the best equipment and materials to build and equip it. It is essential that people ensure the cleanliness of the cleanroom to carry out all research and laboratory work, thus the efficiency of the cleanroom reaches its maximum level.

read more | Ways to Identify Sources of Contamination in Cleanrooms

When the necessary standards for the cleanliness of the cleanroom are met, in addition to increasing the service life of the cleanroom, we will see improvement and upgrading of its efficiency, and for this reason, maintenance, repair, and cleaning of the cleanroom with the help of cleanroom cleaning equipment is essential. The cleaning schedule will usually be on a case-by-case, daily, and weekly basis.

What are the types of equipment required for cleanroom cleaning?

Various cleanroom cleaning equipment are used in cleanrooms. The structure of cleanrooms is such that even the air inside the room is cleaned with the help of special equipment, such as air filters and purifiers. Cleanrooms are also equipped with various devices for testing temperature, environmental pressure difference, and environmental particle counting, and for this reason, it is possible to control the volume of pollutants in the space and eliminate them. In addition, other tools and equipment are used for cleaning and maintenance of cleanrooms, which we will mention below.

Types of Cleaning Supplies for Cleanrooms Cloths

One of the other tools and equipment for cleaning cleanrooms are cloths. It is essential to use special cloths to clean various surfaces in cleanrooms, such as work tables, equipment in the room, etc. These cloths are made of a special material that is highly resistant to disinfectants, and no particles will remain on the environment after the cleaning process is complete.

Cleanroom Washing Buckets

To clean the cleanroom, you can use a bucket that contains various disinfectants and water. When a mop is used to clean the floor, the dirt and pollution in the environment returns to the bucket. Therefore, the best way to prevent the spread of contamination to other surfaces is to use 2 to 3 buckets.

Types of Cleaning Products for Cleanrooms

The selection of cleaning and disinfecting products for cleanrooms is based on the class of the cleanroom, as each of these cleaners and disinfectants has a different effectiveness.

Cleanroom Setup and Equipment with Ekeas Services

In the past, cleanrooms were mostly used in hospitals and medical industries, but due to their unique features, these rooms are now used in a variety of industries. If you are planning to design and implement a cleanroom in your organization, you can use the diverse services of Ekeas Company. Our experts are ready to provide specialized consultancy for purchasing various equipment needed to set up a cleanroom that meets your needs.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: