Humans are the main source of contamination in cleanrooms, accounting for up to 40% of all contamination in cleanrooms. This is true for both particulate contamination and microbiological contamination. Cleanroom clothing acts as an excellent protective barrier, creating a barrier between the individual, the cleanroom, and the product. Therefore, cleanroom personnel must wear special clothing in addition to following hygienic principles. In this article, we will discuss cleanroom clothing.

Employees are often the largest and most important source of contamination when processing products and materials that require a higher level of cleanliness and hygiene. Other sources of contamination can also impact cleanliness levels, but people are the most important source. Four independent sources of contamination can be identified at the product processing site:

Humans (employees) Ambient air Ambient surfaces Product and or process (the main work that employees do)

The four sources of contamination, namely employees, air, surfaces, and product; are all interconnected, as shown by the two-way arrows. In general, all four are equally important, but in practice, it is necessary to see which ones are of the highest importance in relation to the work being done.

read more | cleanroom equipment

Employees can contaminate a product or production process through the surrounding air, direct and indirect contact with various surfaces, and also through direct or indirect contact with the product or process equipment. The most important source of human-origin contamination is the natural process of continuous shedding of epidermal cells.

Cleanrooms and other controlled environments are designed to protect the product, process, or employees from various contaminants and are of great importance. Proper design and construction of a cleanroom is not enough for protection,

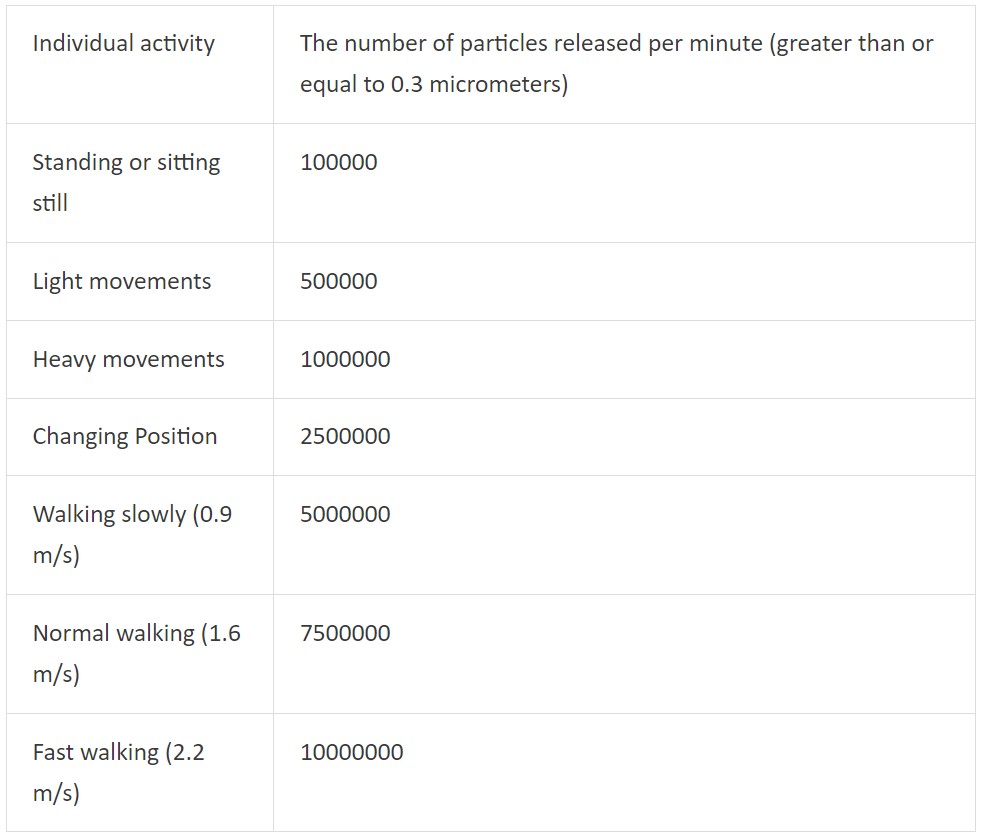

When people enter a cleanroom, the cleanliness of the room changes significantly, as humans produce a significant amount of particles (including non-viable particles and microorganisms), which is largely due to the replacement of the outer layer of skin. The process of replacing the outer layer of skin is continuous and ongoing twenty-four hours a day. It usually takes about four days to replace the entire surface of the skin, which shows that the rate of exchange of this process is very fast. Old skin turns into dried-up skin flakes and, after loosening, separates from the body.

read more | What is a weighing or sampling room

Cleanroom clothes prevent many of these detached flakes from being released and hold them in place. However, some of these particles enter the air of the room around us. During this process, the human body releases between 6 and 13 grams of skin per day. In this way, about 3.5 kilograms of skin is separated from the body annually. The number of particles produced by men is higher than that of women, which is mainly due to hormonal reasons. Also, the amount of skin particles produced by younger people is more than that of older people.

Despite the fact that these flakes are made of dead materials, they are considered to be important contaminants for biosensitive activities (i.e., work with materials and production processes that may be contaminated by microorganisms). This is because the surface of our skin is more or less covered with microorganisms that are part of our natural flora. In practice, this means that even if the released flakes are “dead,” they should also be considered as “viable particles” because they are likely to contain live microorganisms.

read more | Cleanroom stainless steel cabinet

Why is it important to wear cleanroom clothing?

Cleanroom clothing is clothing worn by personnel working in a cleanroom or controlled environment and is considered one of the personal protective equipment. Cleanroom clothing is designed to prevent the release of particle contamination from human body into the cleanroom.

The use of such clothing is essential to protect personnel, especially when they are handling chemical hazards. Cleanroom clothing is typically non-shedding, meaning that it leaves nothing behind. Additionally, these garments are not woven and are completely safe to wear in a controlled environment.

Cleanroom Clothing Requirements

Different types of cleanrooms require different cleanroom clothing. The cleanroom gown protocol is designed to ensure contamination control and compliance with standards such as ISO, EU-GMP. According to the ISO classification, the use of cleanroom gowns is only permitted in ISO Class 7 and ISO Class 8 cleanrooms. Additionally, personnel entering ISO Class 5 and Class 6 cleanrooms must wear cleanroom gowns with a cap, gloves, and boots.

read more | Cleanroom Validation

The material of cleanroom clothes

The purpose of wearing cleanroom clothes is to prevent the spread of human contamination into the cleanroom. The choice of cleanroom clothing material is of utmost importance. For example, natural materials such as cotton are not suitable for use in cleanrooms as they release dust and particles. Instead, synthetic materials are preferred for cleanroom clothing. Three types of synthetic materials are used, depending on the application:

- Woven synthetic fabric: A popular woven fabric for cleanroom clothing is dacron, which is low-cost and durable. This type of fabric is widely used in controlled environments, although the relevant standard may require a different material for clothing in some cleanrooms.

- Non-woven fabric: A popular material for cleanroom clothing is spunbonded polyethylene, also known as Tyvek. This fabric is low-cost, synthetic, and very strong, and provides a good barrier against contaminants and moisture.

- Combination of woven and non-woven fabrics: This combination is found in expanded PTFE laminate materials such as GORE-TEX. This material is very strong, comfortable, and reusable. It also has a long lifespan and can be used in a variety of cleanrooms.

Disposable and washable cleanroom clothes

Cleanroom clothes come in two types: disposable and washable. Washable clothes are washed in a special way to remove contamination so that they can continue to prevent contamination without any damage. Many people ask, “How many times can washable cleanroom clothes be worn?” The answer to this question depends on several factors, including the quality of the water used to wash the clothes. Monitoring the water quality from the last rinse cycle may provide information about the level of contaminants. If the particle level is high, the clothing is expected to be contaminated and should no longer be washed with that water.

read more | Hygienic air conditioner

Observing the amount of dust in the air through a cleanroom dryer can indicate the condition of the clothing. If the air is contaminated, the clothing will also be contaminated. Additionally, there are many methods for testing the effectiveness of washing and the durability of clothing materials, such as the ASTM vacuum filter test, Helmke Drum test, and so on.

On the other hand, high-class cleanrooms choose disposable clothing because it is the safest and most cost-effective option. Disposable clothing should be of high quality and comfortable for employees. A large number of cleanrooms use a combination of washable and reusable clothing. For example, the cleanroom clothing may be washable and reusable, but the shoe covers are discarded after each use. The choice of disposable and washable clothing is determined by considerations such as the type of clothing, comfort, classification, and application of the cleanroom, and so on.

Cleanroom Clothing Selection Method

Even the best cleanroom clothing can cause problems if all the parameters that can affect it are not fully under control. First of all, the material properties should be defined according to the needs. Technical requirements such as high particle retention (impenetrability) and employee concerns about wearing comfort (high breathability) should also be considered.

read more | What is a Pre-filter

In addition, the selection and definition of specific equipment and accessories such as zippers, pockets, etc. should also be taken into account. The environmental conditions of the relevant cleanrooms in which the clothing is to be used also play an important role. Here it is necessary to mention temperature and humidity.

One important point is that the specific requirements of the workplace, for example, special requirements in the field of personal protective equipment, should also be taken into account if necessary. Professional disinfection or cleaning of clothing is an essential part of a cleanroom suit. Staff training is also one of the important features of the effectiveness of a cleanroom suit.

EU GMP and Cleanroom Suit Requirements

Annex 17 of Volume IV of the European Union Good Manufacturing Practice (EU GMP) divides cleanrooms in the pharmaceutical industry into four classes: A, B, C, and D, which are used for different purposes:

- Class A cleanroom is for localized areas that are used for high-risk tasks, such as areas for filling drug ampoules and glass bottles that are subsequently packaged in disinfected conditions. These areas are often composed of different units or worktables with unidirectional airflow.

- Class B cleanroom is for rooms used in filling pharmaceutical packages or processing in disinfected conditions, some of which also have Class A localized areas.

- Class C and D cleanrooms are for cleanrooms dedicated to less sensitive processes that are associated with the production of sterile products.

- Class C cleanroom is for the production of products with contamination risk and is used for filling drug ampoules and glass bottles that are usually sterilized after packaging (for example, in an autoclave.) It is also used in the production of disinfected solutions that have passed through a sterile filter before filling the packages.

- Class D cleanroom is used for the production of solutions and preparation of various components of the filling process. This type of cleanrooms is also used in the production of tablets and the movement of components (for example, after washing.) Class D cleanrooms are also used in the final stage of mass production.

Cleanroom clothing recommended by the EU GMP should meet these requirements:

Class D cleanroom clothing:

- Hair or beard should be covered.

- Standard protective clothing, appropriate footwear, or shoe covers should be worn.

- Appropriate measures should be taken to prevent the introduction of any contamination into the cleanroom.

Class C cleanroom clothing:

- Hair or beard should be covered.

- A one-piece or two-piece blouse and trousers should be worn and closed around the wrists and neck.

- Appropriate footwear or shoe covers should be used.

- Clothing should not release almost any lint or other material.

Class B cleanroom clothing:

- A hat should completely cover the hair or beard and extend into the collar of the blouse.

- A face mask should be worn to prevent the spread of droplets.

- Sterile non-powdered rubber or plastic gloves and sterile or disinfected shoes should be worn.

- Trouser legs and sleeves should be inserted into the shoes and gloves, respectively.

- Protective clothing should not release almost any lint or other material and should prevent the passage of particles produced by the human body.

Recommended procedures and cleanroom clothing

The Institute of Environmental Sciences and Technology (IEST) provides standard procedures for pre-defined applications of biotechnology. All of these documents are developed by the working groups of this institute. Two documents related to cleanroom clothing are as follows:

- 003IEST-RP-CC- “Cleanroom Clothing and Other Controlled Environments Considerations”

- 005IEST PR-CC- “Gloves and Finger Cots for Cleanrooms and Other Controlled Environments”

read more | Cleanroom air shower

General requirements for cleanroom clothing

Cleanroom clothing must meet three main requirements:

- Filtration: Cleanroom clothing must provide a barrier between the wearer and the outside environment, meaning it must be a good enough filter.

- Non-shedding: Cleanroom clothing must be made of materials that do not shed, meaning it should not itself be a source of contamination.

- Comfort: Cleanroom clothing should be as comfortable to wear as possible, meaning it should not be uncomfortable or restrictive.

These three requirements must be considered together, as they can sometimes conflict. The best possible filter is actually a plastic bag that allows no particles or gases to pass through, but such a covering is not comfortable and can be annoying for the wearer! A balance must be struck between filtration efficiency and user comfort, which is one of the most significant advances in the field of cleanroom clothing in the past century.

Most research and surveys in the field of pollution control and cleanroom technology date back to the mid-1960s. A lot has happened since then. Our lifestyles have changed significantly, we have adopted different behaviors, we have adopted newer and more comprehensive personal hygiene practices, the way we wash our clothes has changed, and so on. All of these factors can have a significant impact on the emission of pollutants. But the question is, are these impacts in the direction of improvement or the opposite?

read more | Cleanroom Particle Counting Test

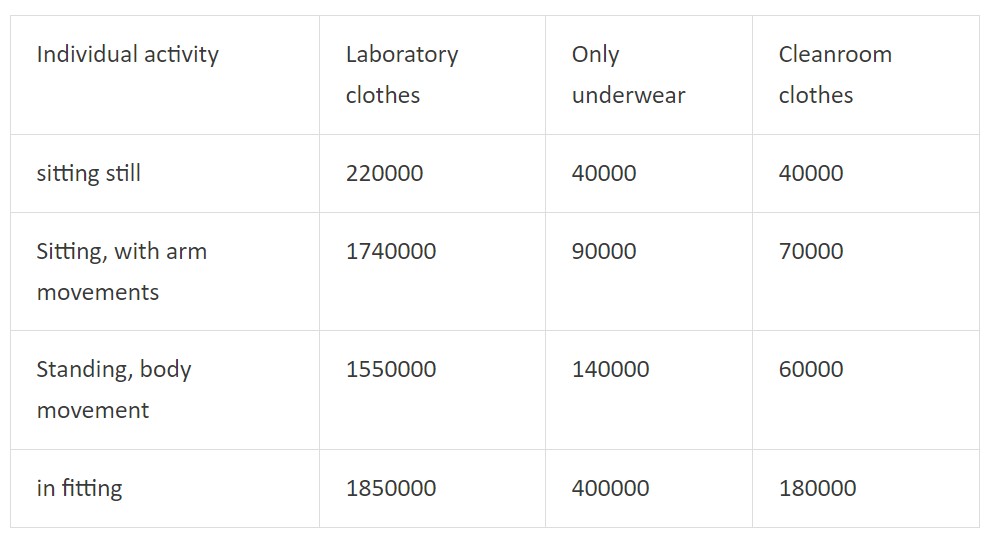

The amount of human pollution (number of particles per minute), in different clothes and during different activities. The diameter of different particles in the air, larger equal to 0.53 micrometers.

Human-derived particles

Humans can be a source of particles and microorganisms in a variety of ways, including:

- Skin

- Microorganisms

- Hair

- Dandruff

- Dry salt crystals from sweat

- Hair styling products

- Shampoo and conditioner residue

- Detergent and fabric softener residue

- Textile fibers

- Cosmetics

- Cigarette smoke

- Saliva

- Stomach gas

- Nasal secretions

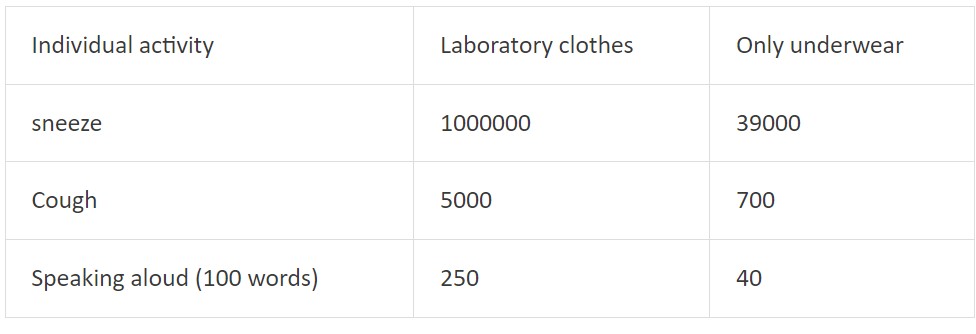

Humans produce a significant number of particles. A large portion of these particles are derived from the outer layer of the skin, but they can also be released into the environment from the mouth and nose (e.g., during breathing, sneezing, coughing, laughing, singing, or yelling). As shown in Table 3, many of the particles released from the mouth and nose are heavily contaminated with microorganisms.

The number of particles that come out of the mouth and nose in different activities.

One of the most effective ways to keep the level of human-derived particles low and, as a result, reduce the risk of product contamination, is to limit the number of people in contact with the process and wear special cleanroom clothing that acts as a barrier and is referred to as “employee filters.” Using clothing that is specifically designed for cleanrooms significantly reduces the number of particles that may be released into the environment. For example, cleanroom clothing may include knee-high boots that fasten below the knee, gloves that prevent the passage of particles, a hat, face protection (face mask), and in some cases eye protection (glasses). Eye protection in the form of glasses reduces the likelihood of particles and droplets produced in the eye being transferred to the surrounding air, which may fall onto the materials being processed due to gravity.

read more | Air-cooled chillers

Another activity that is associated with employees and the creation and deposition of contaminants is the physical contact of the employees’ hands or other parts of their bodies with various surfaces. Particles, grease, and other liquids settle on sensitive surfaces through touch. This type of contamination can be limited by reducing the need for contact with sensitive surfaces and also by using clean gloves or other tools if it is unavoidable to move or touch a surface.

Human Microbiota

Billions of microorganisms live on our skin and in some parts of our body. These organisms are called the body’s normal flora. Since all of these microorganisms live inside and on our bodies, they can be called parasites. However, we also get a lot from their presence. That is, we humans live in harmony and symbiosis with our body’s normal flora. The main question here is what is the benefit of the interaction between the body and its normal flora? For example, the functions of the normal microorganisms inside and on our bodies are as follows:

- Repressing pathogenic organisms (microorganisms that are capable of causing disease on our skin and mucous membranes)

- Producing vitamins in the large intestine

When studying human body microorganisms in detail, it is clear that different parts of the body have significant differences in terms of the presence and number of microorganisms per unit area. This is usually due to differences in the amount of food, humidity, temperature, and oxygen. In a symbiotic relationship, there is always a state of balance. The natural flora of the human body can be divided into the following:

- Skin flora

- Nasal flora

- Eye flora

- Oral and throat flora

- Gut flora

- Urinary tract flora

Ekeas: Supplier of all kinds of cleanroom clothing

Pollutants enter the cleanroom through people and reach the products. For this reason, perhaps the most important point in the cleanroom and maintaining the cleanliness of the environment is the clothing that employees use. Since the goal of the cleanroom is to minimize particles, it is essential to wear cleanroom approved clothing over regular clothing and to cover exposed skin and hair.

Ekeas Group is specialized in the design and implementation of cleanrooms in Iran. We at Akias offer you all kinds of cleanroom equipment with the highest quality and competitive price. For more information about cleanroom clothing, please contact our experts at Ekeas.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: