n sensitive environments such as cleanrooms, it is important to follow strict cleanliness protocols to ensure the safety and well-being of operators, products, and equipment. One of the considerations in cleanrooms is protecting the junctions of walls, ceilings, and floors from accidental impacts and scratches, as well as facilitating cleaning in these areas. This is where cleanroom coves and corners come in. These components provide additional protection for junctions of walls, corners, and edges that are easy to clean. Therefore, in this article, we will become familiar with all aspects of cleanroom coves and corners, from their types to the factors to consider when choosing the best option and other matters.

What are coves and corners and their purpose in cleanrooms?

In cleanroom environments where precision and sterility are of paramount importance, curved covers and junction components for walls, floors, and ceilings play a critical role in creating cleanliness. These innovative and specialized components, known as cleanroom coves and corners, serve a specific purpose that goes beyond mere aesthetic beauty. Understanding the purpose of using these components is essential for maintaining the integrity and cleanliness of cleanroom environments.

read more | Cleanroom stainless steel equipment

One of the main goals of using corner protectors is to protect vulnerable areas from damage. The walls and equipment of cleanrooms are often exposed to accidental impacts and collisions that can compromise their structural integrity and cleanliness. Corner protectors act as sturdy barriers, absorbing impact and protecting these surfaces from damage. These guards help to ensure that cleanrooms remain in optimal condition and free from any contamination or pollutants by preventing dents, scratches, and other forms of damage.

read more | cleanroom equipment

Another important goal of using corner protectors is to facilitate smooth airflow in cleanrooms through the geometric curvature of these components. These connection devices are specifically designed to be aerodynamically efficient and allow airflow around curves and corners. Smooth airflow is essential for maintaining control of the desired particle levels in a cleanroom, as any turbulence or blockage can lead to the accumulation of contaminants. In this way, corner protectors help to clean and improve the overall performance of the cleanroom by ensuring uniform and unobstructed airflow.

Types of Curved Corner Components Available in the Market for Cleanrooms

When it comes to maintaining a clean and safe environment in cleanrooms, curved corners play an important role. These curved connecting components not only improve the aesthetics of the cleanroom, but also create an additional layer of defense against potential damage and contamination. In the market, you will find various types of curved corner components designed to meet the different needs of cleanrooms.

Types of Curved Corner Components Available in the Market for Cleanrooms

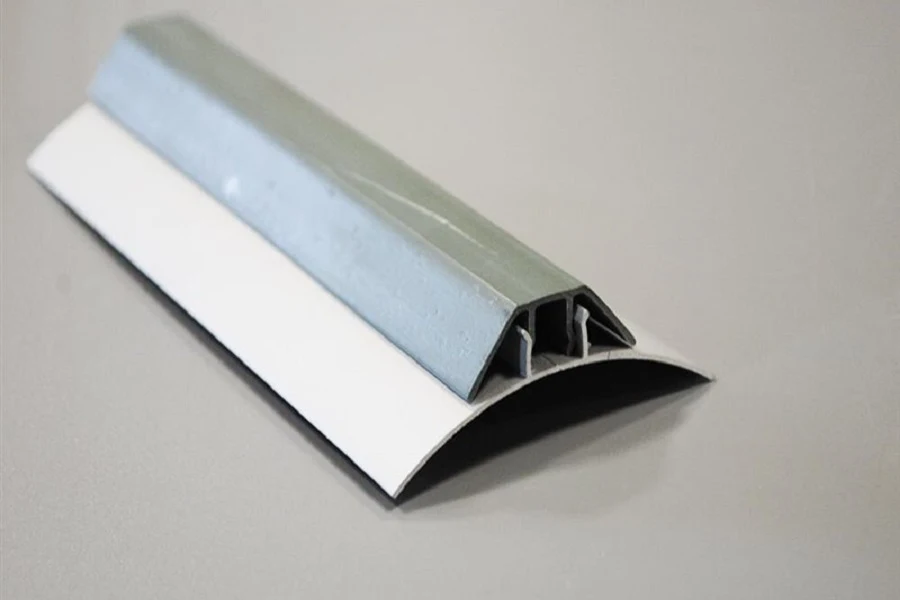

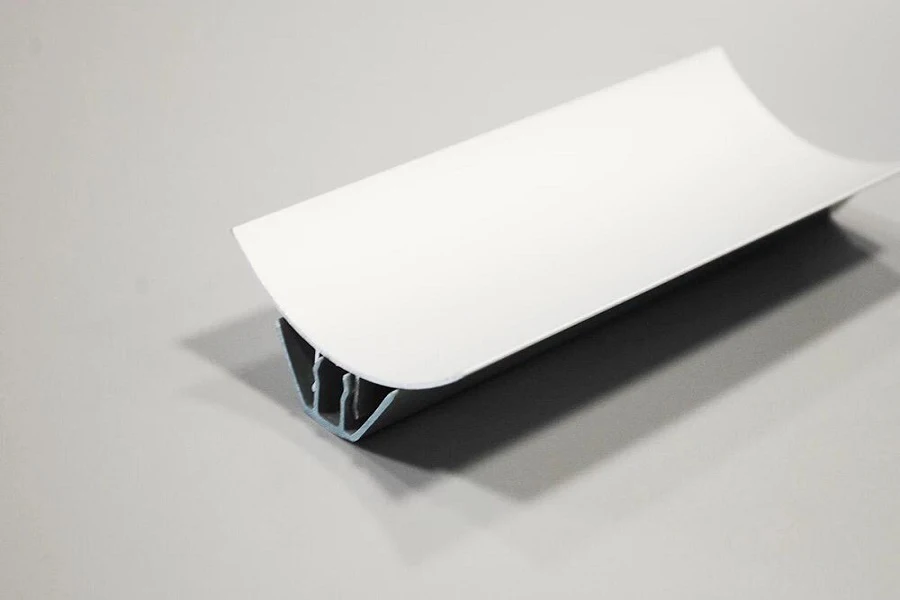

- Rigid PVC corner components: These components are made of durable and rigid PVC material that has excellent impact resistance.

- Flexible vinyl corner components: These corner components are made of flexible vinyl material that allows them to conform to curved lines and wall corners.

- Stainless steel corner components: For cleanrooms with more stringent requirements, stainless steel curved connecting components are an ideal choice.

- Aluminum corner components: These components are lightweight yet sturdy, making them an excellent option for cleanroom applications.

- Silicone rubber corner components: These components are great for cleanrooms that require a high level of cleanliness and hygiene.

Factors to Consider When Choosing Cleanroom Corners and Curves

When choosing cleanroom corners and curves, there are several important factors to consider. These factors can significantly impact the effectiveness, durability, and overall performance of the curved and corner pieces in maintaining the cleanliness and safety of the cleanroom environment.

read more | Cleanroom Particle Counting Test

Some of the factors to consider when choosing cleanroom corners and curves include:

- Materials: The materials used for the corners and curves are very important and should have high durability, easy cleaning, and resistance to chemicals, wear, and impact. Common materials used include stainless steel, PVC, acrylic, and polyurethane.

- Design and installation: The design and installation process of the corners and curves should be seamless and efficient. Look for pieces that are easy to install and preferably without the need for additional tools or complex methods.

- Cleanability: Cleanrooms require a high level of cleanliness, and the corners and curves used should be easy to clean and maintain.

- Compatibility: Make sure the selected corners and curves are compatible with the cleanroom layout and your specific needs. Consider factors such as the desired level of impact resistance, the type of corners or curves that need to be protected, and any requirements related to temperature or humidity conditions in the cleanroom.

Ekeas: A Reliable Source for the Best Cleanroom Corners and Edges

Investing in high-quality corners and curves for cleanrooms is essential for maintaining a sterile and safe environment. These curved and protective connectors offer significant benefits that should not be overlooked. First and foremost, corners and curves provide essential impact protection, reducing the risk of damage to walls, equipment, and surfaces inside the cleanroom. They also provide smooth airflow for contaminant reduction thanks to their aerodynamic properties. The engineering team at Ekeas Cleanroom is ready to provide you with high-quality engineering services at all stages of the design, production, and installation of cleanroom corners and curves and other equipment. So contact us now to take advantage of these services.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: