In industries such as pharmaceuticals, biotechnology, and electronics, maintaining the cleanliness of a cleanroom environment is essential to ensure the quality and safety of products and related processes. Cleanrooms are designed to minimize the introduction of particles, microbes, and other contaminants that can negatively impact the production process. One of the main equipment of a cleanroom is a standard air handling unit (AHU), which is responsible for filtering and circulating air within the room. The use of these AHUs is very important for maintaining a sterile environment and ensuring the integrity of the cleanroom air. In this article, we will become familiar with the importance of using a standard AHU and its role in ensuring the integrity of cleanroom air.

What is a standard cleanroom air handler?

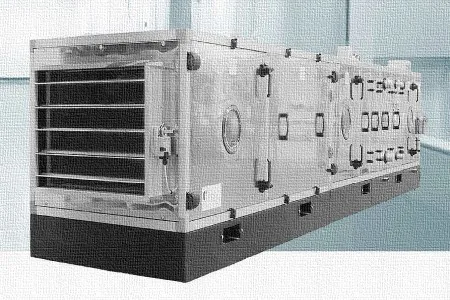

Standard cleanroom air handlers are specialized HVAC (heating, ventilation, and air conditioning) systems that are designed to maintain precise control over air quality in these environments. These units play an important role in industries such as pharmaceuticals, biotechnology, healthcare, electronics manufacturing, and food processing where maintaining a sterile environment and its integrity is critical.

Cleanrooms are controlled environments where the concentration of airborne particulates such as dust, microbes, and pollutants is carefully regulated to ensure product quality, safety, and industrial standards. The standard cleanroom air handler is specifically engineered to meet the exacting cleanliness requirements of these controlled environments.

Air handling units (AHUs) for cleanrooms are designed to provide a controlled environment with low levels of airborne contaminants. These units typically feature advanced filtration systems, such as high-efficiency particulate air (HEPA) filters, which can effectively capture and remove small particles 0.3 microns in size with a efficiency of 99.97% or higher. Additionally, some units may incorporate ultra-low penetration (ULPA) filters, which provide even higher filtration efficiency for very small particles.

read more | Hygienic air conditioner

Standard cleanroom AHUs also have precise temperature and humidity control mechanisms to maintain optimal environmental conditions in the cleanroom. They are designed to continuously supply clean, filtered air while effectively removing contaminants and maintaining sterile conditions.

These units are often equipped with sophisticated monitoring and control systems that continuously monitor air quality parameters, temperature, humidity, pressure differential, and airflow rate. This allows operators to monitor and control the cleanroom environment in real time and quickly identify and address any deviations from required standards.

Role of Standard Cleanroom Air Handling Units in Maintaining a Sterile Environment

Standard cleanroom air handling units play a critical role in maintaining the cleanliness of these controlled environments. These units are specifically designed to control and filter air and ensure that exact sterile conditions are maintained in cleanrooms.

read more | Fan filter box

In cleanrooms, where even the smallest airborne particles can have a significant impact on the final product or process, maintaining sterility is of utmost importance. A standard cleanroom air handling unit is equipped with a high-efficiency particulate air (HEPA) filter that effectively removes small particles from the air. These filters are designed to have high dust holding capacity and ensure that the air remains clean and free of contaminants.

Standard cleanroom air handling units are designed to maintain a positive pressure environment in the cleanroom. This means that the air inside the cleanroom is constantly supplied at a higher pressure than the surrounding areas, which prevents unfiltered air from entering. This positive pressure differential acts as a barrier and prevents the entry of contaminants from external sources.

read more | What is a Bag filter?

To ensure the integrity of the sterile environment, standard cleanroom air handling units are also equipped with advanced features such as air lock systems, pressure differentials, and monitoring systems. These features help to maintain airflow, control temperature and humidity, and ensure that the cleanroom environment is stable and suitable for the processes that are performed inside and for the products.

Ensuring the Integrity of Cleanroom Air with Standard Air Handling Units

When it comes to industries that require stringent cleanliness and sterile environment standards such as pharmaceutical, biotechnology, and semiconductor manufacturing, a standard cleanroom air handling unit plays a critical role in ensuring the integrity of the entire process.

Standard cleanroom air handlers are specifically designed to meet the unique needs of cleanroom environments. They are equipped with advanced filtration systems that effectively remove contaminants from the air, ensuring a clean and controlled environment for sensitive operations.

One of the main functions of standard air handlers is to provide a constant source of filtered air to the cleanroom. This helps to maintain the desired level of cleanliness by removing airborne particles such as dust, bacteria, and other contaminants that can compromise the sterility and integrity of products being manufactured.

Specifications of standard cleanroom air handlers

Standard cleanroom air handlers are essential components in maintaining the sterile environment and integrity of cleanroom operations. These units are specifically designed to meet the stringent requirements of cleanroom facilities, where even the smallest particles can compromise product quality or processes.

read more | What is a HEPA filter?

The main tasks of a standard air handler are to provide sufficient oxygen, remove particles and pollutants from the air, and also provide pressure difference, temperature, and humidity as per the approved conditions of the product. The design and construction of standard air handlers must be approved and comply with important standards such as VDI 6022, VDI 3803, EN 13053, EN 1886, and others.

Standard cleanroom air handling units are generally designed in two types: a full-fresh air system with 100% fresh air and a return air system. Full-fresh air standard air handling units have a thermal recovery mechanism for energy efficiency.

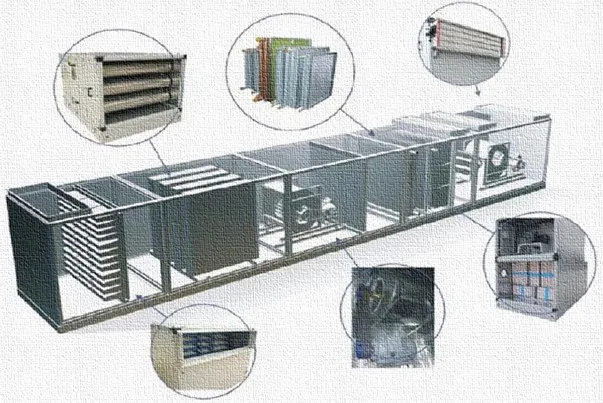

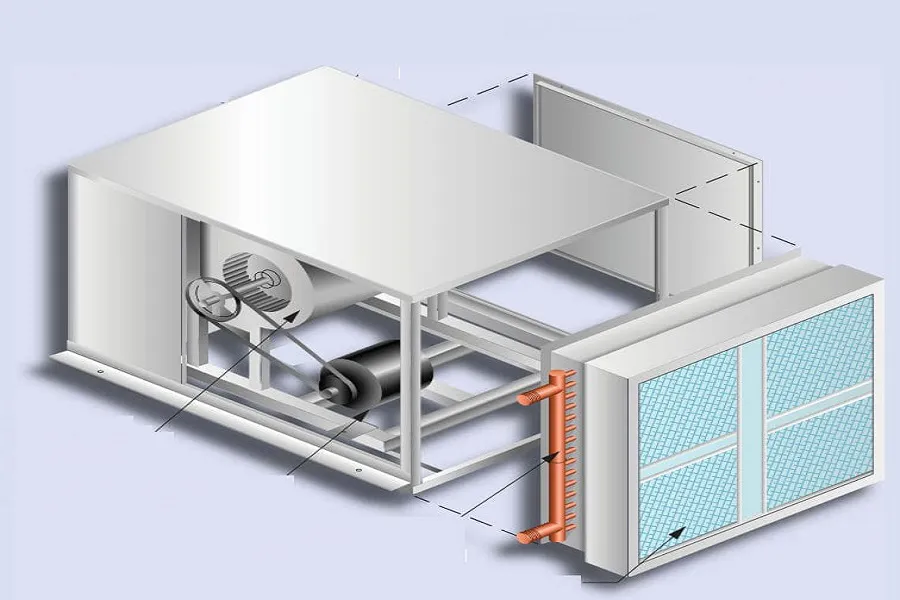

It should be noted that the main components of these air handling units generally consist of the air handling unit inlet and outlet dampers, pre-filter, high-efficiency HEPA filters, ULPA filters, cooling and heating system, air handling unit drip catcher, fan motors, final filter, and air handling unit control equipment.

Airflow control is another vital aspect of standard cleanroom air handling units. These units are designed to provide a constant and uniform airflow throughout the cleanroom space, minimize turbulence, and prevent the formation of any stagnant air in general. Proper airflow management therefore helps to ensure that particles or pollutants generated in the cleanroom are quickly removed and the sterility of the environment is fully maintained.

Benefits of using standard cleanroom air handling units

Standard cleanroom air handling units offer many benefits for industries that require precise control over air quality and a sterile environment. These units are specifically designed to meet the stringent requirements of cleanroom environments and ensure the sterility and integrity of critical processes.

read more | Fan filter unit

One of the main benefits of using a standard cleanroom air handling unit is the ability to maintain a controlled and sterile environment. These units are equipped with advanced filtration systems that effectively remove particles, microorganisms, and other pollutants from the air. In addition, standard cleanroom air handling units are designed to provide constant and precise control over temperature, humidity, and airflow.

Standard cleanroom air handling units are designed with unique energy-saving features, such as variable speed drives and intelligent control systems, that optimize energy consumption to the best extent while meeting the required air quality standards. This benefit not only reduces the associated operational costs in the industries mentioned, but also minimizes the environmental impact of all cleanroom processes and operations.

Tips for Choosing a Standard Cleanroom Air Handling Unit

When choosing a standard cleanroom air handling unit, there are several critical factors that should be carefully considered. As these standard air handling units are a necessity for cleanrooms, selecting the right ones is essential to ensure optimal performance and compliance with industry standards.

First and foremost, the size and capacity of the air handling unit must be appropriate for the specific conditions of the cleanroom. The unit must be able to effectively control the volume of airflow required to maintain the desired level of cleanliness in the cleanroom.

Another important point is the filtration system of the air handling unit. As mentioned, standard cleanroom air handling units typically have multiple stages of filtration, including pre-filters, HEPA filters, and final filters. These filters are designed to remove particles, contaminants, and microorganisms from the air, ensuring that the circulated air in the room remains completely clean and sterile.

Energy efficiency is also a critical factor to consider. Standard cleanroom air handling units should be designed to operate efficiently, minimize energy consumption, and still maintain optimal air quality. Look for units that are equipped with energy-saving features such as variable-speed drives, energy recovery systems, and intelligent control systems.

It should be noted that the construction and materials used in the air handling unit must be compatible with cleanroom standards. Finally, consider the maintenance and service needs of the air handling unit. Regular maintenance and timely servicing are essential to ensure high performance and longer unit life. Look for units that are designed for easy access and maintenance and have features such as removable panels and accessible components.

Maintenance and Optimization of Standard Cleanroom Air Handling Unit Performance

Maintenance and optimization of standard cleanroom air handling unit performance are two very important aspects to ensure the sterility and integrity of the processes in these controlled environments. These specialized units play a vital role in maintaining the desired air quality, temperature, and humidity necessary for proper operation of cleanrooms.

Regular maintenance is essential to prevent any potential problems that could compromise the integrity of the cleanroom environment. This care includes inspecting and cleaning filters, coils, and fans to ensure their optimal performance. Filters should be completely replaced or cleaned in accordance with the manufacturer’s recommendations to prevent the accumulation of contaminants and maintain efficient air filtration performance.

Performance optimization is another key factor in maximizing the effectiveness of air handling units in cleanrooms. This process involves monitoring and adjusting various parameters such as airflow rates, pressure differentials, and temperature and humidity levels. Regular inspection and testing should be performed to identify any deviations from the required standards and take corrective action quickly.

It is worth noting that having a documented maintenance plan and maintaining records of all maintenance activities performed on standard air handling units is absolutely essential. This is because it not only helps to track the unit’s performance over time, but it also helps to comply with regulatory requirements and industry standards.

By prioritizing the maintenance and optimization of the performance of standard cleanroom air handling units, organizations can be confident of the sterility and stability of the integrity of their controlled environments. This not only protects the quality of products and processes within the cleanroom, but it also contributes to the overall safety and well-being of operators and personnel who work in these vital environments.

Ekeas; A reputable source for buying and installing standard cleanroom air handling units

Standard cleanroom air handling units play an important role in maintaining air cleanliness and the integrity of controlled environment operations. These specialized units are designed to meet the stringent requirements of cleanrooms and offer features such as air filtration, temperature control, and humidity regulation. As technology continues to advance, it is expected that we will see further advancements in cleanroom technology. Innovations such as improved filtration systems, intelligent controls, and overall performance and stability will enhance standard cleanroom air handling units.

The engineering team at ekeas cleanroom company can provide valuable engineering services at all stages of cleanroom creation and implementation, including the design and construction of standard cleanroom air handling units and other equipment. So contact us today to take advantage of these services.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: