One of the most important parts of a cleanroom is the weighing or sampling room, where weighing and distribution of materials and samples are performed, and can significantly affect the efficiency of the clean room and the quality of output products. Therefore, in this article, we will become familiar with the importance of the weighing or sampling room in the clean room and in general with the features of this room.

What is a weighing room and the importance of its use in a clean room?

A weighing room with a sound and standard design is a vital component of all clean room facilities. In sterile clean room environments where accuracy in all details is a priority, weighing rooms play a vital role in ensuring optimal efficiency and maintaining the integrity of the clean room.

**One of the main reasons why weighing rooms are essential is their role in preventing any contamination. Clean rooms are highly controlled environments that require strict adherence to cleanliness standards. Therefore, the primary function of weighing chambers is to provide a clean environment that protects the user and the item being measured or sampled from contamination and dust, and also keeps the suspended matter resulting from weighing away from the clean room environment.

read more | cleanroom equipment

Effective weighing room design features air filtration systems, air extraction, and sections to maintain the cleanliness of the space. These measures help to prevent the entry of contaminants that can compromise the accuracy of weight measurement or the overall cleanliness of the clean room.

Some of the uses of sample rooms or weighing rooms include:

- Weighing operations in pharmaceutical companies and laboratories

- Screening and sieving operations

- Separation of powders and liquids

- Filling of tanks with raw materials

- Filling and emptying of reactors, dryers, and granulation

- Grinding and distribution of materials

What features should be considered in the design and production of weighing booths?

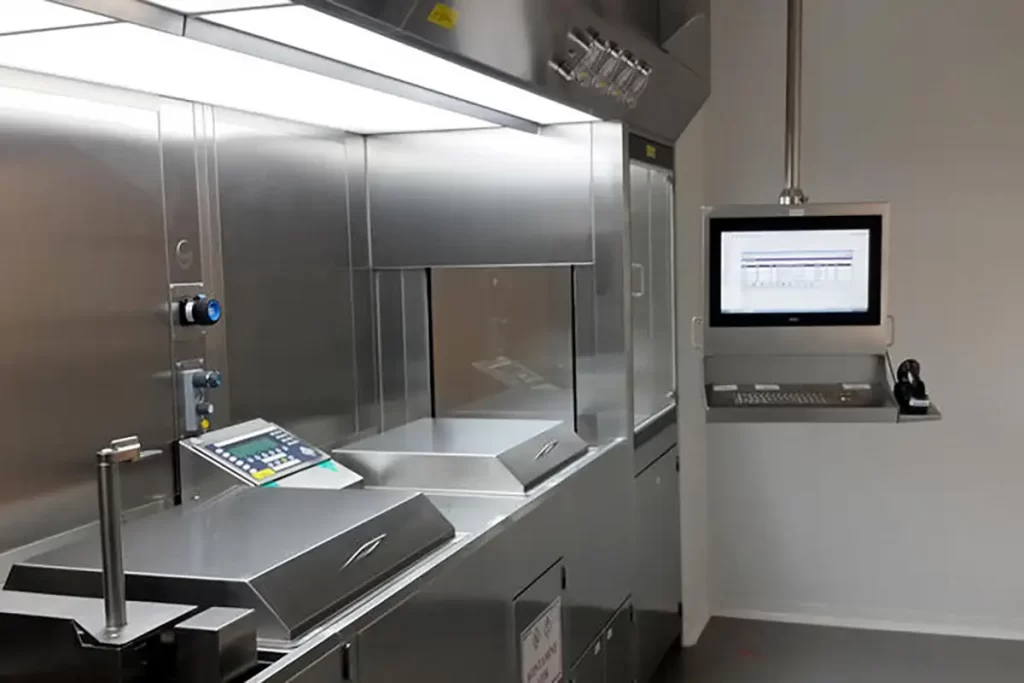

The design of a weighing booth in a cleanroom requires careful consideration of various factors and features such as creating a negative pressure inside the booth to prevent the release of particles into the surrounding environment, creating a specific continuous output speed from the HEPA filter, creating Class A-GMP, creating lighting above 500 lux, and having a system to announce the filling of each filter, including pre-filter, bag, and HEPA, to ensure maximum efficiency and accuracy in the weighing process. In this way, we will become familiar with some of the key factors that should be considered in the design phase of weighing booths.

read more | Cleanroom Validation

Standard Space and Layout

The layout of a weighing room should be optimized for ease of movement and workflow. It should also provide enough space for weighing equipment such as an accurate scale, as well as for operators to perform their tasks comfortably. On the other hand, it should also take into account the placement of cabinets for storing materials and supplies related to the weighing process.

read more | Cleanroom softwall

Contamination Control

Clean rooms are designed to maintain a controlled environment with minimal particle contamination. Similarly, weighing rooms should follow the same principles. Appropriate ventilation systems, air filters, and positive pressure control should be incorporated to ensure cleanliness and prevent cross-contamination.

Ergonomics in Cleanroom Standards

Operator comfort and safety are essential in a weighing room. Ergonomic considerations, such as adjustable workstations and chairs, should be incorporated to minimize physical strain and fatigue during weighing and sampling tasks. This can help improve accuracy and productivity while reducing the risk of injuries caused by repetitive strain.

Proper Lighting

Adequate lighting is essential for accurate weighing and visual inspection of materials. Suitable illumination should be provided to minimize shadows and glare that can impair visibility. Consideration should also be given to the use of specialized lighting, such as anti-static lighting or low-UV lighting, depending on the specific needs of the weighing process.

read more | Portable cleanroom

Compliance with Established Principles and Regulations

Cleanrooms often have specific regulations and standards that must be met. When designing a weighing room, it is important to consider these requirements and ensure compliance with relevant guidelines, such as Good Manufacturing Practices (GMP) or ISO standards.

Long-Term Benefits of Investing in Cleanroom Weighing Chambers

Investing in weighing chambers in cleanroom environments can have countless long-term benefits. The importance of an efficient weighing chamber cannot be overlooked in maintaining the integrity and quality of sample collection and weighing of products in clean environments.

First of all, standard weighing rooms ensure optimum cleanliness and hygiene. By using appropriate air filter systems, smooth surfaces that are easy to clean, and appropriate weighing methods, the risk of contamination can be minimized and the exact cleanliness standards required in cleanroom operations can be met. In addition, weighing chambers increase workflow efficiency. By paying careful attention to the layout and organization of equipment, supplies, and workstations, employees can move seamlessly through the space and reduce the likelihood of errors and delays.

read more | Cleanroom Design

Analysis of the Applications of Weighing Booth

Weighing booths are important systems in clean rooms, and their absence can cause many problems for staff and workflow. Therefore, people should specialize in setting up this efficient system.

The many applications of this room have led to its use in various sections of the clean room, and in this section, we will mention a few of these applications.

- Efficient grinding and distribution of materials in the clean room

- Very useful in laboratories and pharmaceuticals

- Performing screening and sieving

- Emptying and filling reactor, dryer, and granules

Components and elements of the weighing room

- Plastic socket

- Blowing and suction motors

- Steel body

- Equipment and sensors for detecting filter clogging

What are the advantages of a sample room?

- Accelerate work with high safety

- Equipped with warning and fill-up alarm systems

- Apply negative pressure to destroy suspended particles

- Create A-GMP

- Create 500 lux of light

Filters are a key part of clean room equipment. One of these filters is HEPA filter. Click here to learn more.

read more | Cleanroom Cleaning Equipment

How does a weighing room work?

To enter the weighing room, employees must wear special clothes that prevent suspended particles from entering the room from the employees’ clothes.

How a Weighing Room Works

The following is a brief overview of how a weighing room works:

- Raw materials or semi-finished products are transferred from the secondary room to the main room.

- The materials are placed on the scale and weighed.

- The weighing results are recorded.

- The weighed materials are transferred back to the secondary room to be prepared for the next process.

Weighing rooms are an important part of the production process in a variety of industries. They help to ensure the quality and safety of products.

Ekeas Company: The Official Reference for Designing and Manufacturing the Highest Quality Weighing Rooms

The design of weighing rooms in clean rooms plays an important role in maximizing efficiency and maintaining the integrity of this sterile environment. It is essential for organizations in a variety of industries to prioritize the design of weighing rooms to ensure the highest standards of cleanliness, accuracy, and safety. Therefore, the engineering team of Ekeas Cleanroom Company, with the help of experienced and skilled experts in all stages of designing and manufacturing clean room weighing chambers and other equipment required for this sterile environment, is ready to provide you with high-quality and affordable engineering services. Contact us now to take advantage of our services.

Cleanroom Equipment by Ekeas

Cleanrooms include a variety of equipment, and in order for a cleanroom to meet standards, it must use the appropriate equipment. Here are a few examples of cleanroom equipment: